Lithium-Ion Battery R&D Surges as Automation Demand Grows

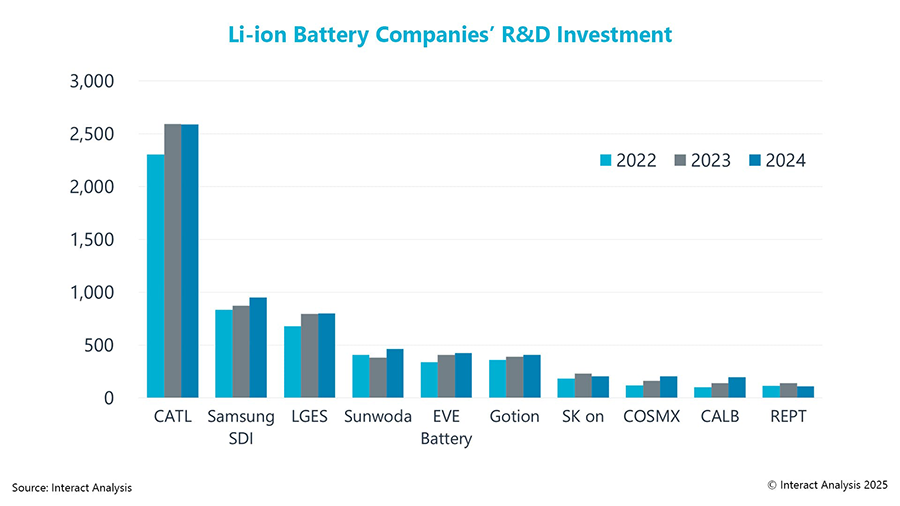

Record R&D Investment in Battery Technology

Global lithium-ion battery R&D spending reaches new heights. Ten leading companies invested over $6 billion in 2024. This represents 17% growth since 2022. The electric vehicle boom drives this innovation race. Energy storage demands also push technological boundaries. Companies seek competitive advantages through research.

Industry Leaders Dominate R&D Spending

CATL leads with massive $2 billion annual investment. This equals the next four competitors combined. Samsung SDI follows with nearly $1 billion. LG Energy Solution spends approximately $800 million. Korean manufacturers show strong commitment. Chinese firms demonstrate rapid growth. Sunwoda and EVE Energy invest heavily.

Emerging Companies Accelerate Investment

CALB shows fastest growth at 41.3% CAGR. COSMX follows with 32.1% expansion. Both companies double down on innovation. However, established players grow more slowly. CATL maintains 6.0% steady growth. REPT actually reduced spending slightly. Market positions influence investment strategies.

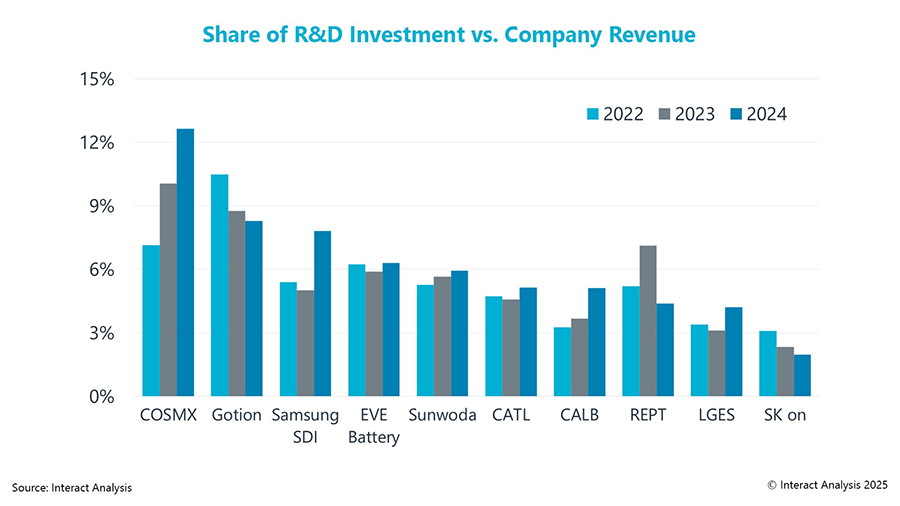

R&D Intensity Reveals Innovation Priorities

R&D to revenue ratio averages 5% across industry. COSMX exceeds 10% intensity consistently. Gotion High-Tech maintains over 8% commitment. Consumer electronics drives high innovation needs. Short product cycles demand constant improvement. Automotive sector shows different patterns. Each segment has unique requirements.

Key Technology Focus Areas for 2024

Companies pursue three main research directions:

✅ Energy density and performance improvements

⚙️ Application expansion into new markets

🔧 Next-generation battery technologies

Material science remains central to progress. Solid-state batteries attract major funding. Sodium-ion alternatives gain attention.

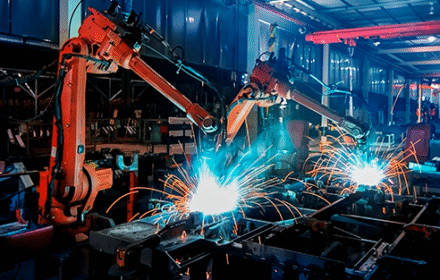

Industrial Automation Role in Battery Manufacturing

Advanced automation enables battery production scaling. PLC systems control precision manufacturing. DCS solutions manage entire production lines. According to IEEE research, automation boosts yield by 25%. Smart factories reduce production costs significantly. Control systems ensure consistent quality.

Future Battery Technology Trends

Solid-state batteries approach commercialization. Sodium-ion offers cost advantages. AI integration accelerates material discovery. MarketsandMarkets predicts $16 billion solid-state market by 2028. Manufacturing automation will be crucial. Production efficiency determines market success.

World of PLC Automation Solutions

Battery manufacturers need reliable control systems. World of PLC Limited provides industrial automation expertise. Our solutions optimize battery production lines. We help achieve higher throughput and quality. Contact us for advanced automation systems. Improve your manufacturing capabilities today.

Automation Applications in Battery Production

✅ Industrial automation transforms battery manufacturing:

PLC systems control electrode coating

DCS manages cell assembly processes

Automated quality inspection systems

Robotics handles material transport

SCADA monitors production parameters

These technologies ensure consistent output.

Frequently Asked Questions

How does automation improve battery manufacturing?

Automation increases production consistency. It reduces human error and improves yield.

Which battery technologies show most promise?

Solid-state and sodium-ion batteries lead innovation. Both offer performance and safety advantages.

What role do control systems play in battery production?

PLC and DCS ensure manufacturing precision. They maintain strict quality standards throughout production.