Universal Robots to Power Next-Gen Laser Welding, Finishing and Plasma Cutting at FABTECH 2025

Universal Robots Transforms Fabrication with Advanced Automation Solutions at FABTECH 2025

Cobot Welding Evolution Accelerates

Universal Robots continues to lead industrial automation innovation. The company recently previewed groundbreaking cobot solutions at FABTECH 2025. According to President Jean-Pierre Hathout, cobot welding has transformed dramatically since 2017. “Today’s systems handle applications considered impossible just years ago,” he stated. The company’s partner ecosystem drives this rapid advancement. Therefore, fabrication workflows are becoming more efficient and sophisticated.

New Robot Platform Sets Performance Benchmarks

Universal Robots unveiled a specialized robot for demanding welding applications. This model delivers exceptional reach, stability, and precision. Moreover, it excels in challenging conditions like long seams and complex parts. The robot debuted across multiple partner booths including Hirebotics and Vectis Automation. As a result, manufacturers can achieve new levels of productivity and quality.

Automated Plasma Cutting Enhances Manufacturing Efficiency

Cobot-powered plasma cutting represents one of automation’s fastest-growing segments. Industry reports indicate the global industrial automation market will reach $306.2 billion by 2027 (MarketsandMarkets). This technology eliminates inconsistencies from manual cutting. Consequently, parts require minimal rework before welding. Key solutions include:

- Hirebotics Cobot Cutter for precise cuts on multiple metals

- Vectis Shape Tool for complex shapes on curved surfaces

- AI-powered path optimization and production analytics

Laser Welding Reaches Mainstream Adoption

Laser welding with cobots is overcoming previous barriers. Improved safety systems and affordable fiber lasers drive this trend. THG Automation’s URW-2LF system demonstrates this progress. It delivers cleaner welds with minimal heat distortion. Additionally, it incorporates laser pre-cleaning for superior results. This represents significant advancement in factory automation capabilities.

Advanced Finishing and Material Handling Solutions

Universal Robots showcases multiple finishing applications at their booth. PushCorp’s system combines a UR30 robot with advanced force control. This enables consistent surface finishing despite part irregularities. Ferrobotics demonstrates active force control for heavier payload robots. The solution supports up to 15 different finishing tools. For material handling, the UR15 robot features Schmalz’s innovative gripper technology. This system reduces compressed air consumption by 80%. Therefore, it offers substantial operational cost savings.

Industry Insights and Educational Opportunities

FABTECH 2025 provides comprehensive learning experiences. Teradyne Robotics’ Will Healy III presents multiple technical sessions. These cover automation implementation and AI integration. Attendees gain practical knowledge about industrial automation trends. Furthermore, they learn about real-world applications and business impacts.

Practical Implementation Scenarios

Manufacturers can leverage these technologies in various applications:

- Automated plasma cutting systems for weld-ready parts

- Laser welding solutions for high-precision joining

- Adaptive finishing systems for complex geometries

- Efficient material handling for sheet metal production

Expert Commentary from World of PLC

The advancements at FABTECH demonstrate cobots’ expanding role in industrial automation. As World of PLC observes, “The integration of AI with robotic systems represents a significant leap forward. These developments make advanced fabrication capabilities accessible to more manufacturers. Companies should evaluate how these technologies can enhance their competitive position.” For comprehensive control systems and automation solutions, explore World of PLC’s product offerings.

Frequently Asked Questions

- How does cobot plasma cutting improve welding quality? It produces consistent edges that require minimal preparation, resulting in stronger, more reliable welds.

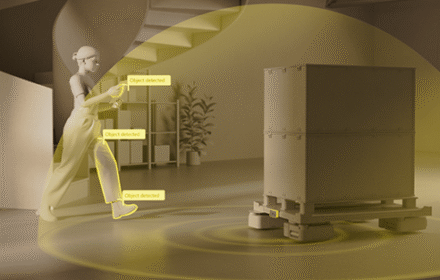

- What safety measures enable cobot laser welding? Advanced control software, integrated safety sensors, and turnkey safety engineering ensure safe operation alongside human workers.

- How can manufacturers start with cobot automation? Beginning with single applications like plasma cutting or material handling allows gradual integration while building operational experience.