Leadership Shift at Trelleborg: Strategic Implications for Industrial Automation

Trelleborg Sealing Solutions recently appointed Gregory Jones as Business Unit President for Industrial Americas. This leadership change signals strategic shifts in the industrial automation sector. Jones brings nearly three decades of sealing solutions expertise to this critical role.

Executive Background and Qualifications

Greg Jones possesses extensive experience in industrial sealing solutions. He joined Trelleborg in 1997 and progressed through sales and engineering leadership roles. His educational background includes molecular biology and MBA degrees from the University of Colorado. This unique combination supports technical understanding of polymer materials and business strategy.

Strategic Vision for Industrial Markets

Jones outlines clear priorities for his new leadership position. He emphasizes customer-focused sales excellence and segment-specific engineered solutions. His vision includes driving sustainable growth through innovation and collaboration. These strategies address evolving needs in factory automation and control systems.

Trelleborg’s Position in Industrial Automation

Trelleborg Sealing Solutions serves critical roles in industrial automation infrastructure. Their precision seals and polymer components ensure reliability in:

- PLC Systems: Protecting control systems from environmental contaminants

- DCS Applications: Maintaining integrity in distributed control environments

- Factory Automation: Supporting robotic systems and manufacturing equipment

- Process Industries: Ensuring sealing performance in harsh conditions

Global Impact and Market Position

Trelleborg Group maintains substantial global presence with SEK 34 billion in 2024 sales. The organization operates approximately 40 countries worldwide. Their industrial solutions directly impact automation reliability and maintenance cycles. According to MarketsandMarkets, the industrial seals market will reach $13.5 billion by 2028.

Industry Implications of Leadership Changes

Executive transitions often signal strategic redirection in industrial companies. Jones’ aerospace background suggests increased focus on high-performance applications. His experience with acquisitions indicates potential growth through strategic partnerships. These moves could influence sealing technology development for automation sectors.

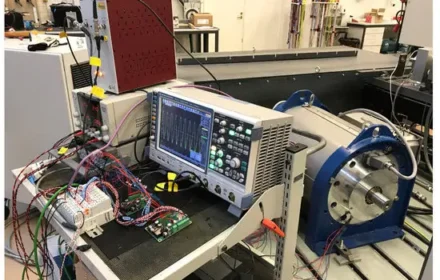

Technical Applications in Control Systems

Trelleborg’s sealing solutions play vital roles in industrial automation reliability. Their products ensure:

- Environmental protection for sensitive control systems components

- Extended service life for pneumatic and hydraulic systems

- Contamination prevention in food and beverage automation

- Reliable operation in semiconductor manufacturing equipment

Expert Analysis: Future Directions

World of PLC analysts observe significant trends in industrial sealing technology. “Leadership changes often accelerate innovation in critical components,” notes our automation team. “Jones’ technical background suggests stronger focus on materials science applications in industrial automation.”

Practical Considerations for Automation Professionals

Industrial automation engineers should monitor these leadership developments. Strategic shifts at component suppliers can impact:

- Product development roadmaps and innovation cycles

- Technical support availability and expertise levels

- Supply chain reliability and delivery performance

- Custom solution development capabilities

For comprehensive analysis of industrial automation components and their applications, explore our resources at World of PLC.

Frequently Asked Questions

How might this leadership change affect Trelleborg’s product development?

Jones’ technical background suggests increased focus on high-performance materials and custom solutions for demanding automation applications.

What industries will benefit most from this leadership transition?

Aerospace, semiconductor, and advanced manufacturing sectors may see enhanced sealing solutions development based on Jones’ previous experience.

How important are sealing solutions in industrial automation reliability?

Critical – precision seals protect control systems from contamination, ensure pneumatic system performance, and reduce maintenance requirements in factory automation.