5G Revolution: Transforming Industrial Automation and Smart Manufacturing in America

By World of PLC — The latest report from the National Association of Manufacturers (NAM) and CTIA reveals how 5G technology is accelerating the modernization of U.S. manufacturing. As factories transition toward Industry 4.0 and smart factory automation, 5G connectivity is becoming the backbone of innovation, safety, and operational efficiency.

5G as the Core Engine of Industry 4.0

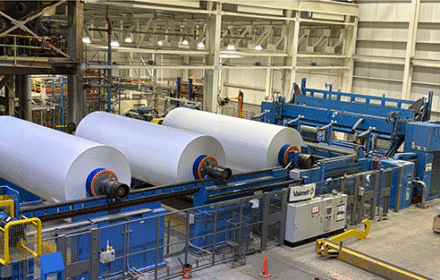

5G networks are enabling faster data transfer, ultra-low latency, and reliable connectivity across factory floors. Manufacturers now integrate 5G into PLC and DCS control systems to achieve real-time monitoring and seamless communication between machines. According to MarketsandMarkets, the global industrial 5G market is expected to surpass $20 billion by 2030, driven by automation and robotics adoption.

Jay Timmons, President and CEO of NAM, noted that 5G empowers manufacturers to enhance safety, boost productivity, and sustain U.S. competitiveness in the global economy.

Empowering Smart Factories with AI and Connectivity

5G supports the deployment of artificial intelligence (AI) and machine learning in industrial automation. These technologies allow predictive maintenance, improved quality control, and real-time optimization of energy usage. A recent IEEE study shows that 63% of manufacturers plan to expand their AI investments by 2027, and 5G provides the data speed and capacity to support these systems effectively.

For example, Hitachi uses a 5G-enabled machine vision system that detects defects smaller than 1 mm in real-time, dramatically improving quality assurance standards.

Real-World 5G Applications in Factory Automation

- ✅ AR/VR Training: VictoryXR and Taqtile use 5G to deliver immersive training programs, enhancing worker safety and engagement.

- ⚙️ Autonomous Robots: Seegrid’s mobile robots, powered by 5G, safely transport parts in Whirlpool’s facilities, freeing workers for higher-value tasks.

- 🔧 Smart Quality Control: Hitachi’s high-definition inspection system leverages AI to identify production defects instantly.

- 🔒 Secure Operations: Cummins uses private 5G networks to protect intellectual property while supporting robotics and remote equipment monitoring.

Economic and Industrial Impact of 5G

According to Boston Consulting Group, 5G will add over $1.5 trillion in GDP and create 4.5 million jobs in the U.S. by 2030. This transformation strengthens America’s industrial base and enhances supply chain resilience. Moreover, 5G integration allows faster scaling of factory automation systems and cloud-based production management.

Expert Insight: Building a Resilient and Connected Future

As World of PLC observes, industrial 5G is not merely about speed—it is about connectivity that enables synchronized decision-making across plants and regions. In practice, 5G bridges the gap between operational technology (OT) and information technology (IT), allowing data from sensors, robots, and PLCs to flow securely through the entire production ecosystem.

However, to maintain this momentum, the U.S. must ensure sufficient mid-band spectrum availability to support growing industrial data demands. Policies that promote 5G infrastructure deployment in manufacturing zones will be critical to sustaining growth and innovation.

Application Scenarios: Industrial Automation with 5G

- Smart factories integrating Siemens PLCs and Rockwell Automation systems with private 5G networks for real-time control.

- Predictive maintenance through AI-driven analytics and connected sensors to reduce downtime.

- Remote diagnostics and cloud-based DCS management improving overall plant efficiency and safety.

To explore PLC, DCS, and control system solutions that align with the latest industrial 5G technologies, visit World of PLC Limited for comprehensive automation products and insights.

Frequently Asked Questions (FAQ)

1. How does 5G improve industrial automation?

5G enables real-time data communication, which enhances precision, reduces downtime, and supports AI integration in production systems.

2. Is 5G secure for manufacturing environments?

Yes. Private 5G networks allow manufacturers to isolate traffic, protect intellectual property, and ensure data integrity within their plants.

3. What are the key challenges for 5G in factories?

Main challenges include high deployment costs, spectrum allocation issues, and the need for interoperability between legacy PLC and control systems.