TDK’s Strategic Expansion: Revolutionizing Industrial Automation with Advanced Vibration Sensors

Market Entry and Strategic Direction

TDK Corporation announces its subsidiary Tronics Microsystems is entering the machine health monitoring sector. This strategic move represents significant evolution for the company. Moreover, it demonstrates their commitment to industrial digital transformation. The vibration sensor market is projected to reach $9.5 billion by 2027 according to MarketsandMarkets research.

Technical Expertise and Legacy

Tronics brings over twenty years of MEMS inertial sensor experience. Their solutions serve aerospace, railway, and energy applications. The company maintains EN 9100-certified manufacturing facilities in France. Therefore, they ensure high reliability standards for industrial customers.

Innovation in Vibration Monitoring

Tronics developed specialized MEMS solutions rather than using basic accelerometers. Their vibration sensors enable predictive maintenance through spectrum analysis. Consequently, manufacturers can detect equipment issues before failure occurs. This approach reduces downtime by up to 50% according to IEEE studies.

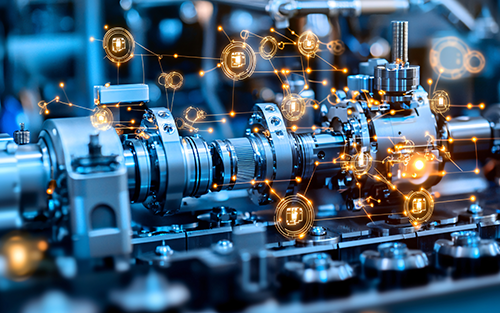

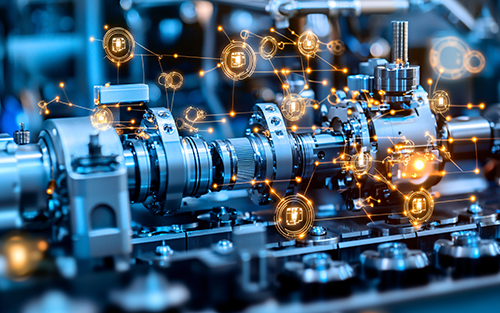

Industrial IoT Integration

The new sensors support condition-based monitoring strategies. They provide continuous health assessment for critical assets. Furthermore, these solutions integrate seamlessly with existing PLC and DCS systems. This creates smarter factory automation environments.

Leadership Perspective

“This expansion leverages our MEMS DNA for industrial applications,” stated Julien Bon, Tronics CEO. “We engineered innovative solutions with precision matching our inertial products. Our approach addresses specific condition monitoring demands from manufacturers.”

Product Development Timeline

Tronics is completing first-generation vibration sensor development. These solutions enable accurate quality control systems. Additionally, they support predictive maintenance implementation. The technology will be showcased at major industry events.

Industry Event Showcases

✅ Electronica India: September 17-19, Bengaluru

✅ SPS Expo: November 25-27, Nuremberg

Visitors can experience live demonstrations at both events. TDK experts will discuss machine health monitoring applications.

Practical Application Scenarios

Manufacturing plants can implement these sensors for:

⚙️ Motor and pump vibration analysis

🔧 Conveyor system health monitoring

✅ Compressor and turbine performance tracking

Early fault detection prevents catastrophic equipment failures.

TDK Corporate Background

TDK Corporation represents a global electronics technology leader. The company has operated for over ninety years. Their tagline “In Everything, Better” reflects continuous improvement philosophy. TDK technologies power numerous industrial and consumer applications.

Tronics Microsystems Profile

Tronics provides comprehensive MEMS inertial sensor solutions. The company employs approximately 100 people in France. TDK Electronics AG holds majority ownership since 2017. Their facilities include complete MEMS manufacturing capabilities.

Industry Implications from World of PLC

This development signals important industry trends. Vibration monitoring becomes increasingly accessible through MEMS technology. Manufacturers should evaluate these solutions for predictive maintenance programs. Furthermore, integration with control systems creates new automation possibilities.

For comprehensive industrial automation solutions, explore product portfolio featuring the latest control systems and monitoring technologies.

Frequently Asked Questions

How do vibration sensors improve predictive maintenance?

They detect abnormal patterns before equipment failure. This enables scheduled maintenance during planned downtime.

What industries benefit most from vibration monitoring?

Manufacturing, energy, and transportation sectors see significant returns. Rotating machinery applications show particular benefit.

How do these sensors integrate with existing automation systems?

They connect through standard industrial protocols. Therefore, integration with PLC and DCS systems is straightforward.