Signal Conditioning Guide for Bently Nevada 3300 XL Proximity Probes

Proper signal conditioning forms the absolute heart of any successful machinery protection system. The Bently Nevada 3300 XL series offers exceptional reliability for vibration and position monitoring. However, we must correctly install and configure these probes to unlock their full potential. This guide walks you through the entire process from setup to verification. It will help you achieve trustworthy data for protecting your critical assets. For all your automation component needs, explore the extensive catalog at World of PLC Limited.

Understanding the System Components

A complete 3300 XL system requires more than just the probe itself. You must understand every component in the signal chain. The system includes the proximity probe, a special extension cable, and a proximitor driver/monitor. The probe generates a radio frequency (RF) signal modulated by the distance to its target. The extension cable then carries this high-frequency signal. Finally, the proximitor conditions this raw signal. It provides powerful outputs like scaled DC voltage and a dynamic AC signal.

Executing a Proper Probe Installation

Always begin with a thorough mechanical and electrical check of the probe and cable. Inspect the probe tip for any signs of damage or wear. Verify the cable’s integrity and ensure its shielding remains intact. We must then install the probe at the correct location and orientation as specified. The most critical step involves setting the probe’s gap voltage. We adjust the probe’s depth in its mounting bracket to achieve the recommended -10 Vdc for the initial gap. This voltage provides the optimal linear range for accurate measurement.

Configuring the Proximitor Driver Settings

The proximitor module does the heavy lifting of signal conditioning. You must configure its settings to match your specific machinery and probe. First, set the desired alarm and danger setpoints based on your machine’s tolerances. Then, ensure the scale factor is correctly set; the standard is 200 mV/mil for vibration and 7.87 V/mm for position. Adjust the output meter ranges to properly display the measured values. Always consult the machinery OEM guidelines for these critical values. They ensure your settings align with the equipment’s design limits.

Verifying System Operation and Calibration

Never assume the system works correctly after installation alone. You must perform a full operational verification. Use a multimeter to check the DC gap voltage at the monitor’s output terminals. Gently tap the probe body while observing the dynamic AC output. This action should produce a clear and responsive signal on your oscilloscope or monitoring tool. This simple test confirms the entire signal path is live and functional. It validates the connection from the probe tip all the way to the control system.

Avoiding Common Pitfalls and Errors

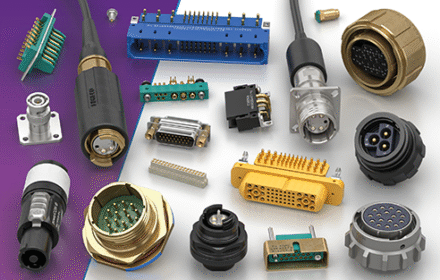

Many common issues can derail an otherwise perfect installation. People often use incorrect or damaged cables that severely degrade the RF signal. Another frequent mistake is poor grounding, which introduces significant electrical noise into the system. Always ensure the target material is ferrous and the correct size for the probe’s sensing area. Avoid running probe cables in the same tray as AC power lines. For reliable spare probes and cables that guarantee performance, consider sourcing from a trusted supplier like World of PLC Limited.

Conclusion: Ensuring Long-Term Reliability

Correct signal conditioning for your Bently Nevada 3300 XL probes is a fundamental skill. It directly impacts the health of your machinery and the effectiveness of your predictive maintenance program. By following these steps for installation, configuration, and verification, you will generate highly accurate data. This practice protects your valuable assets from catastrophic failure and unplanned downtime. Remember to periodically re-check your system’s calibration to ensure long-term reliability. Investing in quality components from the start pays for itself many times over.