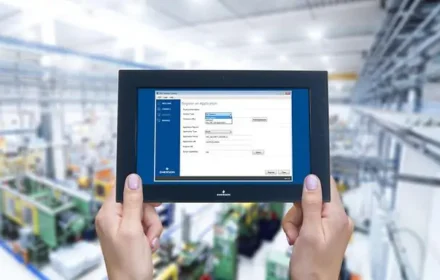

Understanding the GE RX3i and SCADA Landscape

The GE RX3i PLC is a powerful controller. It is key in modern industrial automation. Connecting it to SCADA systems is crucial. SCADA, or Supervisory Control and Data Acquisition, provides system visibility. This integration allows for remote monitoring and data logging. Therefore, successful connection improves operational efficiency. Moreover, the RX3i supports various control systems protocols. This flexibility makes it ideal for complex factory automation needs. We must master these protocols for effective system integration.

Leveraging Modbus for GE RX3i Connectivity

Modbus is a widely accepted, simple protocol. It facilitates communication between the RX3i and SCADA. Both Modbus TCP (Ethernet) and Modbus RTU (Serial) are common options. Modbus TCP is faster and offers network flexibility. Setting up Modbus requires careful address mapping. You must map PLC registers to SCADA points correctly. Furthermore, robust data integrity is essential for reliable operation. This legacy protocol remains a staple in PLC to SCADA links.

Implementing Ethernet/IP for High-Speed Data Exchange

Ethernet/IP offers high-speed data exchange. It is a favored choice in many industrial settings. This protocol builds upon standard Ethernet technology. The GE RX3i natively supports Ethernet/IP. Thus, it simplifies integration with devices from ODVA members. Ethernet/IP uses “objects” for data representation. This structure streamlines configuration and maintenance. As a result, systems achieve faster update rates. This speed is vital for time-critical DCS applications.

Integrating Profinet for European and High-Performance Systems

Profinet is common in European industrial automation. It offers deterministic real-time performance. The GE RX3i integrates Profinet through specific communication modules. Profinet utilizes a provider-consumer model for data transfer. It ensures precise synchronization across the network. Profinet IO is excellent for demanding motion control. Moreover, its robustness supports complex distributed systems. Integrating Profinet expands the RX3i’s application scope globally.

Author’s Insight: Protocol Selection and Future Trends

Choosing the right protocol is critical. Consider network topology, speed requirements, and installed base. Modbus is simple but less feature-rich. Ethernet/IP and Profinet offer superior performance and standardization. I see a clear trend toward Ethernet-based solutions. They simplify network architecture dramatically. However, security protocols are paramount for all industrial networks. Companies must implement strict access controls. Furthermore, leveraging these protocols ensures future-proof control systems.

Application Scenario: Water Treatment Plant

A municipal water treatment plant uses GE RX3i PLCs. They control filtration and pumping. SCADA integration via Ethernet/IP provides operators real-time data. Operators monitor tank levels and flow rates remotely. The high-speed protocol ensures immediate alarm reporting. As a result, response times to critical events improve greatly. This reliable data link optimizes chemical dosing precision. This application showcases the value of robust factory automation.

Discover the right hardware and solutions for your GE RX3i integration project.

World of PLC Limited specializes in industrial automation parts and solutions. Click here to explore our range of GE RX3i modules and industrial communication gateways that make SCADA connectivity seamless.