Festo Integrated Automation Solutions Streamline Semiconductor Wafer Production

Innovative Automation Solutions for Semiconductor Wafer Production

The semiconductor industry demands unprecedented precision and reliability in manufacturing processes. Festo’s latest demonstration showcases how integrated automation systems can streamline wafer handling and processing while maintaining sub-micron accuracy. This approach addresses critical challenges in semiconductor fabrication, where contamination control and positioning precision directly impact yield rates. According to MarketsandMarkets, the semiconductor automation market is projected to reach $12.8 billion by 2027, growing at a CAGR of 7.3%.

Advanced Wafer Handling and Alignment Technology

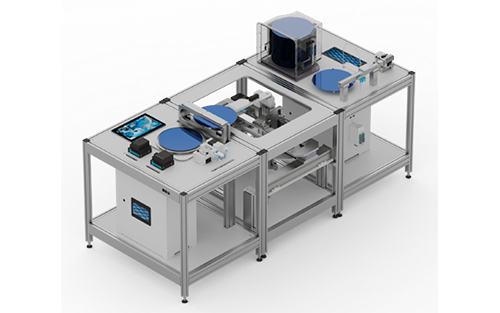

Semiconductor manufacturing begins with precise wafer handling. Festo’s central hub utilizes an inverted gantry system that provides a cost-effective alternative to SCARA robots. This system efficiently transfers wafers from FOUP carriers to processing stations with exceptional speed and accuracy.

Moreover, the integrated wafer end effector combines gripping and alignment functions in a single compact device. This innovative design reduces system complexity while ensuring sub-micron positioning accuracy before subsequent processing steps.

Precision Coating and Wet Process Automation

After alignment, wafers proceed to coating and wet chemical processes. The system incorporates several advanced technologies to ensure optimal results:

- Festo Mass Flow Controllers maintain clean environments through precise FOUP purging

- Electric linear axes provide smooth nozzle movement across wafer surfaces

- “Suck-back” solutions prevent chemical dripping and ensure even coating distribution

This combination significantly reduces chemical waste while improving coating uniformity. As a result, manufacturers can achieve higher throughput with consistent quality.

Vacuum Processing and Micro-Positioning Systems

For vacuum-based processes like dry etching, Festo’s second module demonstrates critical capabilities. The system gently controls slit and gate valves during wafer transfer into vacuum chambers.

Inside these chambers, pneumatic pin lifts carefully position wafers on chucks with minimal vibration. Additionally, pneumatic micro-positioning systems achieve micrometer-level accuracy when placing focus rings. These capabilities ensure stable process conditions essential for advanced semiconductor manufacturing.

Industry Impact and Technical Expertise

Festo’s comprehensive approach addresses multiple semiconductor manufacturing challenges. The company provides solutions for both front-end and back-end processes, including cleanroom-compatible components and nitrogen purge systems.

Furthermore, their digitalization initiatives incorporate AI for process optimization and predictive maintenance. Industry reports from IEEE confirm that such integrated automation approaches can improve overall equipment effectiveness (OEE) by up to 15% in semiconductor fabrication facilities.

From my perspective at World of PLC, Festo’s demonstration highlights several important industry trends. The integration of multiple functions into single devices represents a significant advancement in automation design. This approach reduces mechanical complexity while improving reliability.

Practical Applications and Implementation Scenarios

Manufacturers can implement these automation solutions in various semiconductor processing contexts:

- Wafer fabs requiring high-speed transfer between multiple process stations

- Cleanroom environments where contamination control is paramount

- Research facilities developing next-generation semiconductor devices

- Production lines implementing Industry 4.0 principles and data collection

For comprehensive automation solutions including PLC programming and system integration, visit World of PLC to explore our product offerings and technical resources. Our expertise in industrial automation can help you implement similar advanced systems in your manufacturing environment.

Frequently Asked Questions

How does Festo’s inverted gantry compare to traditional SCARA robots?

The inverted gantry provides similar precision at a lower cost while offering greater flexibility in system layout. This makes it particularly suitable for space-constrained manufacturing environments.

What advantages does the integrated wafer aligner provide?

By combining alignment and gripping functions, the system reduces mechanical complexity, minimizes potential contamination points, and improves overall reliability while maintaining sub-micron accuracy.

How do Festo’s solutions address cleanroom requirements?

The company offers specifically designed cleanroom-compatible components that minimize particle generation and incorporate effective purge systems to maintain stringent cleanroom standards throughout the manufacturing process.

Festo’s demonstration is a significant leap forward, particularly the integration of gripping and alignment into a single end-effector. This directly tackles the perennial semiconductor challenge of minimizing mechanical complexity to boost reliability and reduce contamination. In my experience consulting for mid-sized fabs, the cumulative downtime from maintaining separate alignment stations and grippers is a major, often underestimated, cost sink. I recall a specific client struggling with yield issues traceable to particulate generation from their legacy, multi-component handling system. By transitioning to an integrated approach similar to Festo’s, they projected not only a 10% reduction in maintenance cycles but also a measurable improvement in yield by minimizing handling-induced defects. The sub-micron accuracy claim is impressive, but the real-world value for many manufacturers will be the system’s inherent simplicity. This makes it a compelling solution for fabs looking to modernize without the exorbitant cost of a full cleanroom rebuild. The mention of a 15% OEE improvement from IEEE is entirely plausible when you consider the reduction in non-value-added alignment steps and the potential for more predictive maintenance, as hinted at with their AI initiatives. This is precisely the kind of practical innovation the industry needs to scale efficiently.