Open Standards Revolutionize Industrial Automation with Flexible AMR Integration

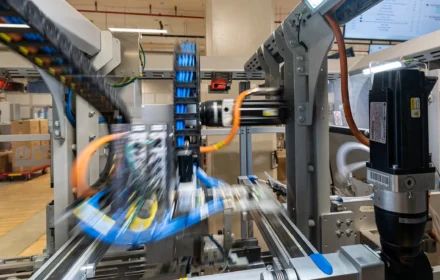

The Challenge of Mixed Fleet Automation

Modern factories face significant integration challenges. According to MarketsandMarkets, the global AMR market will reach $18.7 billion by 2030. However, operators struggle with mixed fleet management. Different vehicle types and manufacturers create compatibility issues. These challenges demand flexible, vendor-neutral solutions.

VDA 5050 Standard Enables Seamless Integration

The VDA 5050 communication protocol serves as a universal translator for mobile robots. This open standard allows different AMRs to communicate with centralized control systems. Bosch Rexroth’s ROKIT Navigator ensures complete VDA 5050 compliance. The software enables standardized communication across all integrated vehicles. Moreover, ROKIT Locator provides centimeter-accurate positioning.

Successful Implementation with K.Hartwall AMR

The recent integration demonstrates practical benefits. K.Hartwall’s A-MATE Lite now operates seamlessly within the SYNAOS platform. The entire onboarding process required minimal time and customization. This efficiency stems from the open architecture approach. Consequently, companies can deploy mixed fleets faster and cheaper.

Expert Analysis: Why Open Standards Matter

As World of PLC analysts observe, “The industry is shifting from proprietary systems to open standards. This transition mirrors earlier developments in PLC and DCS evolution. Companies that embrace open architectures future-proof their operations. They also gain significant cost advantages in long-term maintenance and expansion.”

Benefits for Different Stakeholders

Open standards create advantages across the automation ecosystem:

- Operators gain vendor independence and system flexibility

- OEMs reduce development time using modular components

- System integrators deploy solutions faster with standardized interfaces

- Facility managers can mix and match best-in-class equipment

Real-World Applications and Use Cases

The integrated solution supports various industrial scenarios:

- Material handling in manufacturing facilities

- Warehouse logistics and inventory management

- Just-in-sequence production line feeding

- Cross-docking operations in distribution centers

For comprehensive industrial automation solutions, explore our control systems and PLC programming services.

Implementation Best Practices

Successful AMR integration requires careful planning:

- Assess current material flow patterns first

- Choose VDA 5050-compliant equipment whenever possible

- Plan for gradual implementation and staff training

- Establish clear performance metrics and KPIs

Future Outlook for Industrial Automation

The collaboration between Bosch Rexroth, SYNAOS and K.Hartwall signals broader industry trends. Open standards will continue driving interoperability. Furthermore, modular approaches will dominate future automation projects. Companies should therefore prioritize flexibility in their automation roadmaps.

Frequently Asked Questions

What is VDA 5050 and why is it important?

VDA 5050 is an open communication standard for mobile robots. It enables different AMRs to work together seamlessly within the same fleet management system.

How long does typical AMR integration take?

With VDA 5050-compliant systems, integration time can reduce from weeks to days. The K.Hartwall implementation demonstrated this accelerated timeline.

Can legacy equipment work with modern AMR systems?

Yes, through appropriate interfaces and gateways. However, native VDA 5050 support provides the most straightforward integration path.