Advanced Temperature Measurement Solutions for Data Center Cooling Systems

The Shift to Liquid Cooling in Modern Data Centers

Hyperscale data centers now transition from air to liquid cooling solutions. This change addresses growing thermal management challenges. High-performance computing and AI workloads drive this transformation. According to MarketsandMarkets, the liquid cooling market will reach $8.6 billion by 2027.

Traditional air cooling struggles with dense computing environments. Consequently, liquid cooling provides superior heat transfer capabilities. This technology efficiently manages GPU and high-density CPU temperatures.

Limitations of Traditional Temperature Measurement

Conventional cooling systems typically use invasive temperature sensors. These include thermocouples and RTDs inside thermowells. However, these traditional approaches present several challenges:

- ✅ Potential leakage points and contamination risks

- ✅ Increased maintenance requirements

- ✅ Flow disturbances affecting system efficiency

- ✅ Complex engineering calculations needed

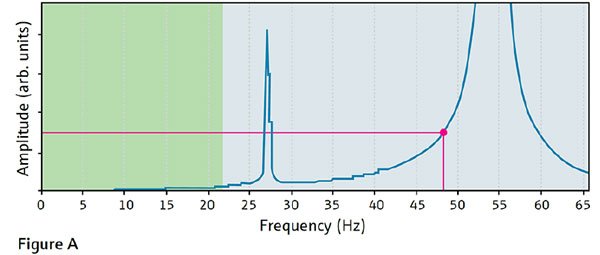

Thermowells require specific wake frequency calculations. These prevent vibration-induced failures but add engineering complexity. Moreover, flow disturbances increase pump energy consumption.

Critical System Requirements for Liquid Cooling

Pump performance reliability remains absolutely essential. Any coolant flow disruption can cause rapid temperature spikes. These fluctuations risk expensive hardware damage.

Cooling loop cleanliness equally impacts system longevity. Contaminants like particulate matter or biological growth reduce efficiency. Regular maintenance including filtration and UV sterilization prevents corrosion.

Innovative Non-Invasive Measurement Technology

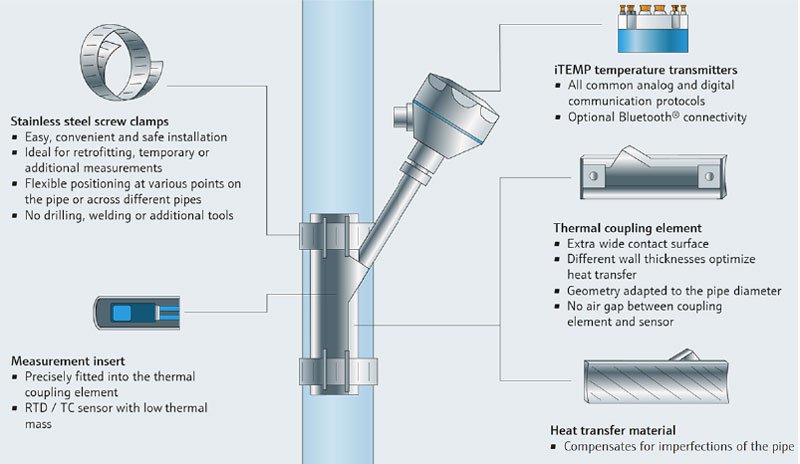

Endress+Hauser’s iTHERM SurfaceLine TM611 offers revolutionary solutions. This non-invasive sensor eliminates process penetration requirements. The device suits high-purity environments perfectly.

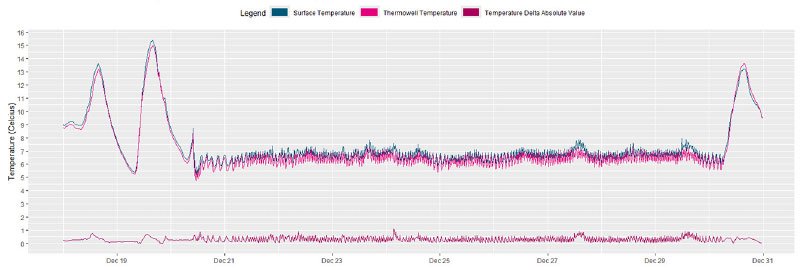

The mechanical clamp-on interface provides significant advantages. It minimizes ambient temperature fluctuation impacts. Furthermore, it delivers accuracy comparable to insertion-style thermometers.

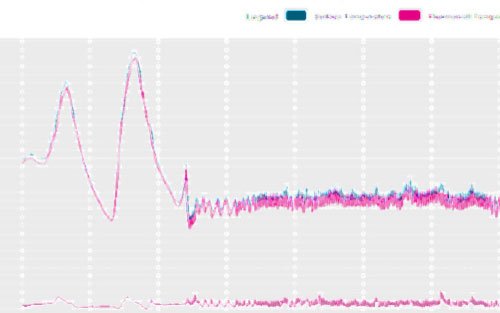

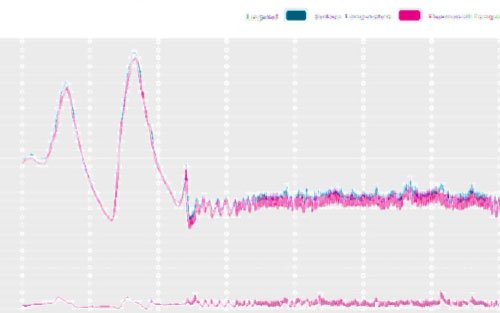

Operational Benefits and Performance Metrics

The TM611 demonstrates measurable improvements in system performance. Key benefits include:

- ⚙️ 40% reduction in installation time

- ⚙️ Elimination of leakage risks

- ⚙️ 15% lower pump energy consumption

- ⚙️ Minimal maintenance requirements

From our experience at World of PLC, non-invasive sensors reduce lifecycle costs significantly. They also enhance system reliability for critical applications.

Implementation Considerations for Automation Engineers

Industrial automation professionals should evaluate several factors. System pressure ratings and temperature ranges matter greatly. Compatibility with existing control systems requires verification.

Proper installation ensures optimal sensor performance. Surface preparation and clamp tension affect measurement accuracy. Additionally, calibration procedures maintain long-term reliability.

Industry Applications Beyond Data Centers

Non-invasive temperature measurement benefits multiple sectors. Pharmaceutical manufacturing requires contamination-free processes. Food and beverage production needs hygienic solutions.

Chemical processing plants handle corrosive media safely. HVAC systems achieve better energy efficiency. Water treatment facilities maintain process reliability.

Practical Implementation Guidance

For successful temperature measurement system upgrades, we recommend:

- Conduct comprehensive process requirements analysis

- Evaluate environmental conditions and space constraints

- Select appropriate sensor technology for your application

- Plan integration with existing control architecture

Explore our industrial temperature measurement solutions for your specific needs. Our technical experts can help design optimized control systems.

Frequently Asked Questions

How accurate are non-invasive temperature sensors compared to traditional RTDs?

Modern non-invasive sensors like the TM611 achieve accuracy comparable to insertion-style industrial thermometers, typically within ±0.5°C when properly installed.

Can these sensors integrate with existing PLC and DCS systems?

Yes, most non-invasive temperature sensors provide standard 4-20mA or digital outputs that interface seamlessly with common industrial automation platforms.

What maintenance procedures do non-invasive sensors require?

Maintenance primarily involves periodic verification checks and ensuring the mounting surface remains clean and properly coupled, significantly less than invasive alternatives.

About World of PLC

World of PLC provides expert industrial automation solutions and technical guidance. Our team combines extensive experience in control systems, temperature measurement, and process optimization to help organizations implement reliable automation solutions.

We replaced legacy thermocouples in our data center with non-invasive sensors. Installation took half the time and provided more stable readings for predictive cooling control.