Global Manufacturing Faces Uncertainty While Industrial Automation Adapts

Manufacturing Growth Stalls Amid Trade Policy Shifts

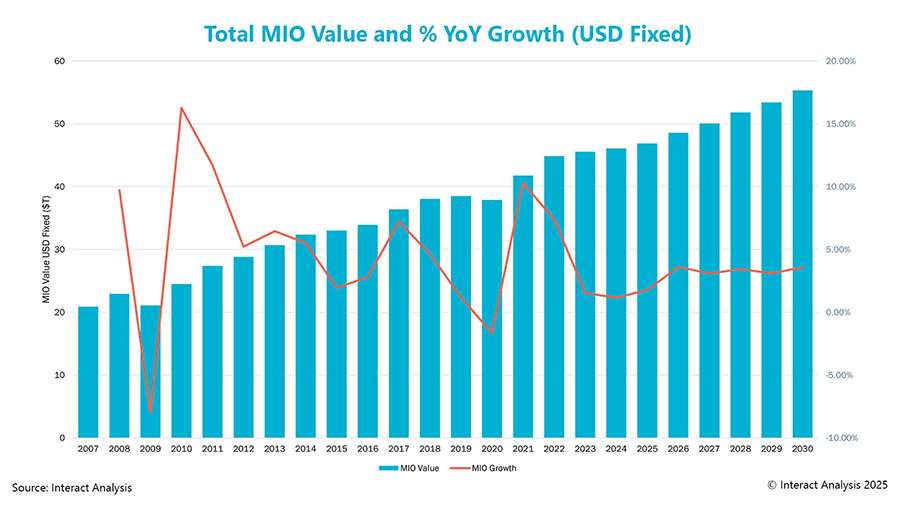

Recent market intelligence reveals manufacturing growth remains stagnant. According to Interact Analysis, Q2 2025 shows minimal improvement. Global manufacturing output should reach 2% growth this year. However, uncertainty around US trade policies continues affecting investment. Europe faces slight contraction while China and the US show stronger performance. This creates challenges for industrial automation suppliers.

Regional Manufacturing Performance Diverges Significantly

Major European manufacturing economies face stagnation. Germany, France, the UK and Italy show limited growth. However, smaller European countries demonstrate stronger performance. Poland, Spain and the Czech Republic are gaining market share. Meanwhile, APAC semiconductor hubs benefit from AI investment. The region shows robust growth potential through 2030. According to Statista, AI in manufacturing will reach $16.7 billion by 2027.

Machinery Sector Faces Dual Challenges in 2025

Two primary factors impact global machinery production. Elevated interest rates created excess inventory levels. This led to extended destocking periods across the industry. Additionally, new US tariffs disrupt potential recovery. Machine orders saw temporary spikes before tariff deadlines. However, production will likely decline post-implementation. Industrial automation companies must adapt their strategies.

Industrial Automation Opportunities Emerge

Despite challenges, several growth areas exist for automation. Nearshoring investments create new manufacturing opportunities. Companies seek resilient supply chains and automation solutions. Control systems like PLC and DCS remain essential. They help manufacturers improve efficiency during uncertainty. According to MarketsandMarkets, the industrial automation market will reach $306.2 billion by 2027.

Expert Analysis: Manufacturing Outlook for 2025-2026

Jack Loughney of Interact Analysis provides key insights. “Economic uncertainty has impacted global manufacturing,” he states. “Despite challenges, we expect 2.1% growth in 2025.” From World of PLC’s perspective, automation technology becomes crucial. Manufacturers must invest in flexible control systems. These systems help adapt to changing market conditions quickly.

Practical Applications: Automation Solutions for Current Challenges

Manufacturers can implement several strategies today:

✅ Upgrade PLC systems for better production flexibility

⚙️ Implement predictive maintenance to reduce downtime

🔧 Optimize DCS configurations for energy efficiency

📊 Deploy industrial IoT for real-time monitoring

These approaches help manufacturers navigate uncertain conditions effectively.

Future Outlook: Industrial Automation Trends

The manufacturing sector continues evolving rapidly. AI-driven automation investments are increasing globally. Companies seek to reduce labor costs and improve quality. According to IEEE research, smart factories will boost productivity by 30%. Industrial automation providers must offer comprehensive solutions. This includes PLC programming, system integration, and technical support.

World of PLC Solutions for Modern Manufacturing

Current market conditions demand reliable automation partners. World of PLC Limited provides essential industrial automation solutions. Our expertise helps manufacturers optimize their operations. We offer advanced PLC systems and control technologies. These solutions improve production efficiency during challenging times. Contact us to enhance your manufacturing capabilities today.

Frequently Asked Questions

How are US tariffs affecting industrial automation investments?

Tariffs create uncertainty, causing manufacturers to pause capital expenditure decisions temporarily.

Which regions show the strongest growth for industrial automation?

APAC regions, particularly semiconductor hubs, demonstrate robust growth driven by AI investments.

What automation technologies help during economic uncertainty?

Flexible PLC systems, predictive maintenance, and energy-efficient DCS configurations provide the most value.