International Robot Safety Conference 2025: Advancing Industrial Automation Safety

The Association for Advancing Automation hosts its annual safety conference. This event addresses critical robot safety standards. Industrial automation demands proper safety protocols. The conference occurs November 3-5 in Houston, Texas.

New Safety Standards for Industrial Automation

The R15.06 2025 standard takes center stage. This update adopts ISO 10218 requirements. Manufacturers and integrators must understand these changes. The standards affect all industrial robot applications. Therefore, compliance becomes essential for operations.

Expert-Led Technical Sessions

Over 40 safety professionals will present. Representatives include FANUC, Universal Robots, and Amazon. NVIDIA and Procter & Gamble experts will share insights. These sessions provide practical safety knowledge. Moreover, they address real-world automation challenges.

Key Sessions Include:

- Engelberger Award winner Stuart Shepherd’s keynote

- Deep dive into R15.06 2025 standard changes

- Expert panel with industry leaders

- AI safety and cybersecurity workshops

- Mobile robot risk assessment techniques

Critical Learning Objectives

Attendees will gain current safety knowledge. They learn to protect workers in automated environments. The conference covers risk assessment methods. It also addresses cybersecurity requirements. Furthermore, networking opportunities enhance learning.

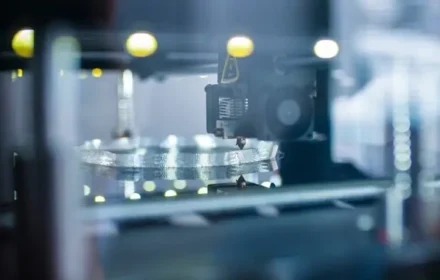

Industry Growth and Safety Importance

Robot installations continue increasing globally. The International Federation of Robotics reports record growth. Proper safety measures become increasingly crucial. New technologies like AI require updated protocols. As a result, safety standards must evolve constantly.

World of PLC Professional Perspective

Industrial automation specialists recognize safety’s fundamental role. Proper implementation requires understanding control systems. PLC and DCS integration must consider safety protocols. The new standards affect system design approaches.

Explore industrial automation safety solutions at World of PLC. Our expertise helps implement compliant systems effectively.

Practical Implementation Scenarios

Manufacturing Facilities: Implement safety-rated monitoring systems for robot cells. Integrate emergency stop circuits with PLC control systems.

System Integrators: Design safety circuits that meet R15.06 requirements. Validate system safety before commissioning.

End Users: Develop maintenance procedures compliant with new standards. Train personnel on updated safety protocols.

Essential Safety Components

- Safety-rated PLC and relay systems

- Emergency stop circuits

- Safety light curtains and barriers

- Risk assessment documentation

- Validation and verification protocols

Frequently Asked Questions

Who should attend the Robot Safety Conference?

Manufacturing engineers, system integrators, safety professionals, and automation specialists benefit most.

What are the key changes in R15.06 2025?

The standard incorporates ISO 10218 updates and addresses new technologies like AI and mobile robots.

How does robot safety integrate with control systems?

Safety systems work with PLC and DCS controls to ensure compliant operation and emergency response.