Advanced Power Management Solutions for Industrial Automation Systems

Addressing Modern Power Management Challenges

Mouser Electronics collaborates with Analog Devices on a new ebook. This resource explores power management for digital devices. Modern industrial automation requires sophisticated power solutions. Furthermore, processors and FPGAs demand efficient power supplies. The ebook details how ADI meets these growing demands. It covers high-density power management innovations thoroughly.

Key Power Management Components Featured

The ebook highlights several critical ADI components. These address various industrial automation needs:

- LT8627SP synchronous step-down regulator

- MAX16165 and MAX16166 voltage sequencers

- LT3074 dropout linear regulator with PMBus

- LTM4700 µModule regulator for high-current applications

- Silent Switcher 3 technology for noise reduction

Advanced Regulator Technology

The LT8627SP features innovative Silent Switcher 3 technology. It provides ultralow noise design and EMI emissions. The device offers sixteen-amp current rating. This enables multiphase buck configurations effectively. Moreover, it operates at switching frequencies above one megahertz. This benefits ripple, size, and bandwidth significantly.

Power Sequencing and Monitoring

MAX16165 and MAX16166 devices monitor up to five voltages. They sequence four voltages with adjustable delays. These components provide crucial power management capabilities. Additionally, they support daisy-chaining for system expansion. This allows control of any number of voltages efficiently.

Industrial-Grade Linear Regulation

The LT3074 dropout linear regulator offers exceptional performance. It features wide bandwidth and high PSRR. The PMBus serial interface enables digital control. Furthermore, VIOC technology manages upstream switching regulators. This minimizes power dissipation substantially.

High-Power Module Solutions

The LTM4700 µModule regulator delivers impressive power capacity. It provides dual fifty-amp or single hundred-amp operation. The innovative heatsink packaging increases server density. According to industry reports, data center power demands grow twenty percent annually. Therefore, efficient power management becomes increasingly critical.

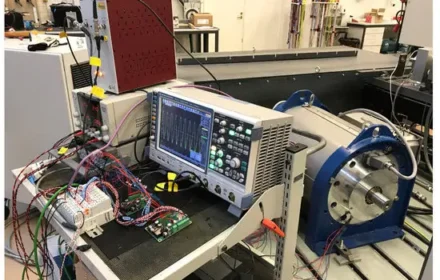

Expert Analysis from World of PLC

Proper power management is fundamental to industrial automation reliability. Control systems like PLCs and DCS require clean, stable power. Voltage fluctuations can cause catastrophic system failures. In my experience, selecting appropriate power components prevents downtime. For professionals designing industrial systems, World of PLC offers comprehensive automation resources. These help engineers implement robust power solutions effectively.

Industrial Application Scenarios

These power solutions serve multiple industrial applications:

- Factory Automation: Powering PLCs and motor controllers reliably

- Process Control: Supporting DCS and instrumentation systems

- Data Acquisition: Providing clean power for measurement systems

- Motor Drives: Enabling efficient power conversion for motors

Implementation Recommendations

Consider these practices for industrial power design:

- Select regulators with adequate current margins

- Implement proper sequencing for multiple voltages

- Use components with industrial temperature ranges

- Consider EMI requirements for sensitive applications

- Plan for adequate heat dissipation in enclosures

Frequently Asked Questions

Why is power sequencing important in industrial systems?

Proper sequencing prevents latch-up and ensures reliable startup. It also protects sensitive components from voltage spikes.

How does Silent Switcher technology benefit industrial applications?

It reduces electromagnetic interference significantly. This prevents noise from affecting sensitive control systems.

What advantages do µModule regulators offer?

They simplify design by integrating multiple components. This reduces development time and improves reliability.