Understanding RX3i Industrial Ethernet Topology

RX3i systems often use star or linear network topologies. Each topology presents unique failure points. Understanding your specific network layout is the first critical step. This knowledge directs your troubleshooting efforts effectively.

Essential Tools for Network Diagnostics

You need the right tools for effective diagnosis. A managed switch with port monitoring is invaluable. Furthermore, a simple cable tester can quickly isolate physical layer problems. These tools save significant time during an outage.

Diagnosing Physical Layer Connection Issues

Always check physical connections first. Look for damaged cables, loose connectors, or faulty RJ45 ports. Inspect the status of the link lights on the RX3i controller and switch. A missing link light often indicates a physical layer fault.

Resolving IP Address Configuration Conflicts

IP conflicts are a common source of network failure. Verify that each device, including the RX3i CPU, has a unique IP address. Moreover, ensure all devices are on the same subnet. An incorrect gateway setting can also prevent communication.

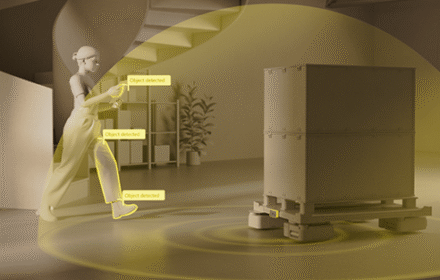

Analyzing Switch and Network Infrastructure Health

Network switches can fail or become misconfigured. Check for switch port errors, broadcast storms, or faulty VLAN settings. Industrial-grade switches from manufacturers like Cisco or Moxa provide detailed diagnostic counters. These counters help identify problematic network segments.

Interpreting RX3i PLC Communication Status

The RX3i controller provides diagnostic information. Use Proficy Machine Edition software to check the controller’s communication status. This software shows connection timeouts and protocol-specific errors. Therefore, it is a central point for diagnosis.

(Author’s Insight & Commentary)

In my experience, over half of all “network” issues are actually physical. Vibration in industrial environments gradually loosens connectors. I recommend using managed Ethernet switches exclusively. Their diagnostic capabilities provide the visibility needed for proactive maintenance in harsh factory automation settings.

A Real-World Troubleshooting Scenario

A packaging line’s RX3i PLC intermittently lost communication with its remote I/O drops. The link lights flickered erratically. Technicians replaced switches and controllers without success. The root cause was a single damaged Ethernet cable passing near a motor drive. Replacing the shielded, industrial-grade cable permanently resolved the issue.

(Conclusion and Call to Action)

A structured approach to Industrial Ethernet troubleshooting minimizes RX3i system downtime. Start with the physical layer and move logically through the network stack. This method ensures a swift return to normal operation.

Struggling with persistent network instability? World of PLC Limited supplies reliable, industrial-grade networking components perfect for RX3i systems, including managed switches and ruggedized cables. Build a more resilient network with our proven products. Browse our selection and find a solution at https://worldofplc.com/.