Advanced Drive Solutions for Bulk Material Handling Operations

Meeting Demanding Industrial Automation Requirements

Bulk material handling faces extreme environmental challenges. Temperature variations and abrasive conditions demand robust solutions. NORD delivers customized drive systems for these harsh applications. Their modular approach ensures optimal performance in demanding conditions.

High-Performance Stockyard Drive Systems

Stockyard operations require reliable buffering and storage solutions. These systems serve critical industries like mining and cement production. NORD engineers specifically consider material properties and operating conditions. Their solutions include advanced technological features:

- UNICASE helical bevel gear units for heavy-duty applications

- MAXXDRIVE XC industrial gear units with high torque capacity

- NORDAC FLEX decentralized frequency drives

- NORDAC PRO SK 500P control cabinet drives

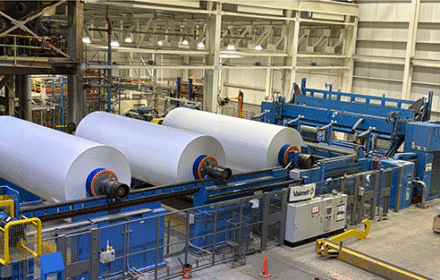

Efficient Bulk Material Conveying Solutions

Conveyor systems form the backbone of material transport. They handle everything from aggregates to powders efficiently. NORD designs drives for all conveyor configurations. Their engineering approach considers multiple critical factors:

- Mass flow rate requirements and conveyor length

- Horizontal, vertical, and inclined applications

- Output torques up to 2,495,900 lb-in for large systems

- Compact solutions for smaller conveyor needs

Precision Weighing and Metering Control

Accurate material dosing requires intelligent control systems. NORD drives enable precise mass flow adjustments. Their frequency drives incorporate advanced positioning technology. These systems offer significant operational advantages:

- POSICON integrated positioning mode for accuracy

- Plug-and-play installation with bus system connectors

- Integrated PLC for automatic blockage detection

- Reverse/forward operation for material jam clearance

Robust Loading and Unloading Applications

Port and terminal operations demand high-torque solutions. NORD drives power critical loading equipment reliably. Their systems ensure maximum availability in harsh conditions. Specialized protection features enhance durability:

- Heavy-duty housings sealed against moisture ingress

- Corrosion-resistant components for extended life

- Dust-protected brakes with continuous monitoring

- Double canopies for motor fan protection

Industry Trends and Market Analysis

The global material handling equipment market continues expanding rapidly. According to MarketsandMarkets, this market will reach $217.2 billion by 2027. Industrial automation drives this growth significantly. Companies increasingly seek energy-efficient solutions that reduce operational costs.

Expert Insight: Drive System Selection Criteria

Selecting appropriate drive systems requires careful analysis. At World of PLC, we recommend evaluating several key factors. Environmental conditions and load requirements are paramount. Maintenance accessibility and energy efficiency also matter significantly. Explore our industrial drive solutions for optimized material handling performance.

Frequently Asked Questions

What torque range do NORD drive systems cover?

NORD produces drives for torques from 88 lb-in to over 2.5 million lb-in, serving diverse applications.

How do integrated PLCs improve material handling?

Integrated PLCs enable automatic blockage detection and clearance routines, reducing downtime.

What industries benefit from these drive solutions?

Mining, cement production, power generation, and grain handling industries all utilize these robust systems.

Conclusion: Reliable Performance in Demanding Conditions

NORD drive systems demonstrate exceptional durability in bulk material handling. Their modular approach allows customized solutions for specific applications. These systems ensure continuous operation while minimizing maintenance requirements. The extensive product portfolio serves diverse industrial needs effectively.