Agricultural Automation Revolution: $4 Million Investment Transforms Animal Feed Production

Strategic Automation Partnership Announcement

JR Automation has invested over $4 million in Forever Feed Technologies. This strategic partnership will deploy eight automated grow systems. Each system produces sprouted grain for animal feed. The collaboration combines agricultural innovation with industrial automation expertise.

Revolutionary Feed Production Technology

The FFT Grow System represents cutting-edge agricultural automation. Each unit produces 50 tons of feed daily. This system uses 95% less water than traditional methods. Moreover, it eliminates dependence on seasonal field production.

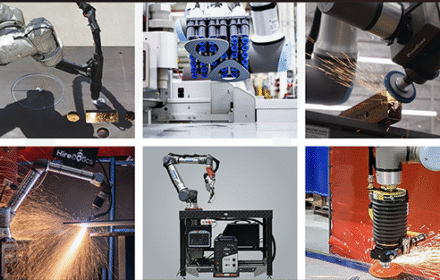

Industrial Automation Meets Agriculture

JR Automation brings advanced control systems to agriculture. Their expertise includes PLC programming and DCS integration. These systems ensure precise environmental control. Consequently, feed quality remains consistent year-round.

Environmental Impact and Sustainability

This technology addresses critical resource challenges. One FFT system replaces 700 acres of farmland. It significantly reduces water consumption and transportation emissions. Therefore, it supports sustainable agriculture goals effectively.

Economic Benefits for Livestock Operations

Farmers achieve substantial cost reductions through automation. They minimize feed transportation expenses. Additionally, they gain independence from market price fluctuations. The system pays for itself through operational efficiencies.

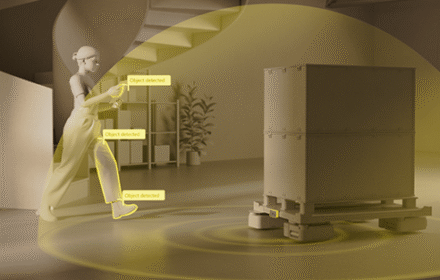

Technical Specifications and Capabilities

The automated grow systems feature advanced components:

Precision climate control systems

Automated watering and nutrient delivery

Real-time monitoring sensors

PLC-based process control

Remote operation capabilities

Industry Context and Market Growth

The global agricultural robotics market will reach $20.6 billion by 2028. This represents a 22.8% CAGR according to MarketsandMarkets. Industrial automation drives this agricultural transformation. Smart farming solutions are becoming essential.

Implementation Timeline and Deployment

Core component orders will be placed in Q4 2025. The first system demonstrated success in October 2024. Multiple deployments will follow on large dairy operations. This accelerated timeline shows automation efficiency.

Expert Commentary from World of PLC

This partnership demonstrates industrial automation’s expanding applications. Agricultural operations increasingly require sophisticated control systems. For advanced automation solutions across industries, explore World of PLC. Our expertise ensures successful system integration.

Future Applications and Expansion Potential

The technology has significant expansion possibilities. It could adapt to various crop types and regions. Furthermore, the automation platform supports scalability. This investment signals agriculture’s automated future.

Frequently Asked Questions

How does automated feed production improve efficiency?

Automation enables continuous production with minimal labor while maintaining consistent quality and reducing resource consumption.

What control systems are used in these agricultural applications?

The systems utilize industrial PLCs and DCS platforms with precision sensors and automated control algorithms.

Can this technology be scaled for smaller operations?

While designed for large-scale production, the technology can be adapted for various operation sizes through modular design approaches.

This analysis demonstrates how industrial automation transforms traditional agriculture. Always consult with automation experts for specific implementation requirements.