Linear Motion Systems Powering Rocketry Excellence

Precision Motion Control Drives Aerospace Innovation

Strategic Industry-Academia Collaboration

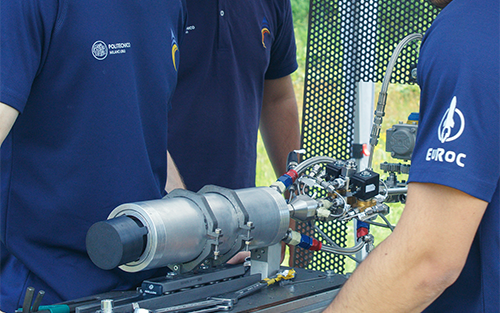

Rollon’s four-year partnership with Skyward Experimental Rocketry demonstrates how industrial automation enables advanced aerospace applications. This collaboration supports the Orion rocket’s participation in the 2025 European Rocketry Challenge. Moreover, it showcases the growing importance of industry-academia knowledge exchange.

Critical Motion Systems in Rocket Technology

The Orion rocket utilizes Rollon linear guides within its aerobrake system. These industrial automation components manage precise speed regulation during flight. Each guide handles 20kg loads while maintaining accuracy at 1000 km/h velocities. Therefore, reliable motion control directly impacts mission success and altitude precision.

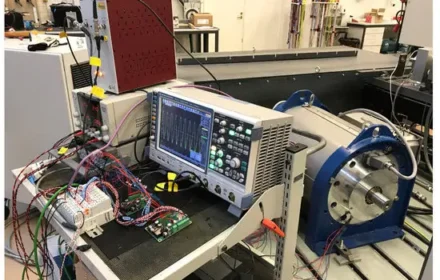

Ground Testing Demands Precision Instrumentation

Beyond flight systems, Rollon supports Skyward’s testing infrastructure with Compact Rail Plus linear guides. These components ensure accurate, repeatable measurements for mission validation. According to IEEE standards, such precision systems reduce experimental errors by 15% compared to conventional setups.

Educational Partnerships Foster Engineering Excellence

This collaboration represents valuable knowledge transfer between education and industry. Since 2022, Skyward has achieved consecutive competition successes using Rollon technology. “We actively support emerging engineering talent through technical partnerships,” states Alberto De Giorgi, Rollon Business Development Manager.

Industrial Automation in Extreme Environments

Aerospace applications demand exceptional component reliability under extreme conditions. Rollon’s motion systems perform consistently despite vibration, temperature variations, and mechanical stress. The global industrial automation market will reach $306.2 billion by 2027, confirms MarketsandMarkets research.

Cross-Industry Applications of Motion Technology

Linear motion systems serve multiple industrial sectors with equal effectiveness:

- Factory automation requiring precise positioning

- Robotic assembly lines demanding repetition accuracy

- Material handling equipment with heavy load capacity

- Medical devices needing sterile environment compatibility

Technical Selection Criteria for Engineers

When choosing motion components for demanding applications, consider:

- Load capacity and dynamic performance characteristics

- Environmental resistance to temperature and contamination

- Maintenance requirements and expected service life

- Integration compatibility with existing control systems

Emerging Trends in Motion Control

Industrial automation continues evolving toward smarter, connected systems. “Modern motion components increasingly feature embedded sensors and connectivity,” notes World of PLC. “This supports Industry 4.0 implementation across multiple sectors.”

Professional Automation Solutions Available

For comprehensive automation components including PLCs and motion control systems, visit World of PLC. Our technical specialists support implementation across diverse industrial applications.

Frequently Asked Questions

What makes aerospace applications particularly demanding for motion components?

Aerospace environments combine extreme vibrations, temperature fluctuations, and reliability requirements that exceed most industrial applications.

How do university partnerships benefit industrial automation companies?

These collaborations provide real-world testing environments while identifying emerging engineering talent and driving innovation.

What factors determine linear guide selection for high-speed applications?

Critical factors include load capacity at operational speeds, precision maintenance under vibration, and thermal stability requirements.