Industrial AI Analytics Revolution: Seeq Leads Manufacturing Transformation

Seeq earns leadership position in Verdantix Green Quadrant for Industrial AI Analytics, demonstrating excellence in manufacturing intelligence and process optimization.

Verdantix Recognition Highlights AI Leadership

Seeq Corporation has achieved leader status in the Industrial AI Analytics market. Verdantix awarded this recognition in their 2025 Green Quadrant report. The independent research firm evaluated nineteen technology vendors thoroughly.

Verdantix employed a comprehensive assessment methodology. Their process included live product demonstrations and customer interviews. They also conducted detailed vendor questionnaires and secondary research.

Key Strengths in Industrial Analytics

Seeq earned exceptional scores across multiple categories. The platform demonstrated superior data processing capabilities. It also excelled in model development and user interface design.

The solution received perfect scores for indirect data acquisition. Its 3.0/3.0 rating highlights technical excellence. Over fifty high-performance connectors enable seamless integration.

Seeq’s pharmaceutical analytics suite gained special recognition. This GMP-compliant version serves life sciences manufacturers. It addresses specific regulatory requirements effectively.

Industry Expert Validation

Verdantix analyst Henry Kirkman praised Seeq’s approach. He noted the platform’s ability to handle operational technology data. The system avoids complex data migration projects successfully.

Kirkman emphasized Seeq’s data-first analytics methodology. This approach naturally supports predictive maintenance initiatives. It also drives significant process optimization gains.

Executive Perspective on Market Leadership

Seeq CEO Dr. Lisa Graham expressed honor in the recognition. She credited the company’s dedicated team and customer trust. The achievement reflects their commitment to industrial innovation.

Dr. Graham highlighted Seeq’s core mission. The platform streamlines access to enterprise data. This enables subject matter experts to generate measurable value quickly.

Proven Track Record of Excellence

This recognition continues Seeq’s award-winning streak. The company has accumulated multiple prestigious honors recently. These achievements reinforce their market position strongly.

Notable awards include several key recognitions:

- 2025 Frost & Sullivan Customer Value Leader

- G2’s Top 50 UK Software Companies 2025

- IoT Breakthrough Analytics Innovation Award

Industrial Applications and Use Cases

Seeq serves numerous process manufacturing industries. Their technology drives digital transformation across sectors. Key applications demonstrate substantial business impact.

The platform enables critical manufacturing improvements:

- Production yield optimization

- Quality control enhancement

- Energy efficiency improvements

- Sustainability initiative support

- Predictive maintenance implementation

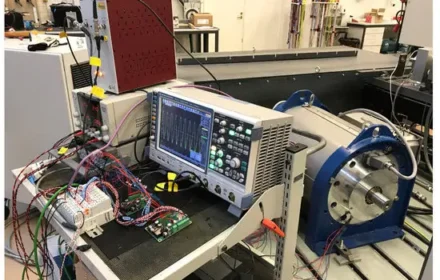

Integration with Industrial Control Systems

Seeq connects seamlessly with existing factory automation infrastructure. The platform integrates with PLC and DCS systems effectively. This ensures minimal disruption during implementation.

From our perspective at World of PLC, Seeq’s approach aligns with modern industrial trends. The platform complements traditional control systems perfectly. It enhances data visibility without replacing existing investments.

Industrial organizations benefit from several integration advantages:

- Leverages existing control system infrastructure

- Provides unified view of operational data

- Enables advanced analytics without system replacement

- Supports gradual digital transformation

Market Position and Global Reach

Seeq maintains strong market momentum according to the report. The company scored above average in strategic categories. These include market vision and product strategy areas.

The company serves customers across forty countries worldwide. A global partner network supports international deployments. Direct sales teams cover North America and Europe primarily.

Implementation Considerations for Manufacturers

Manufacturers should consider several factors when evaluating industrial analytics. The integration process requires careful planning and execution. Proper preparation ensures successful outcomes.

Key implementation steps include:

- Assess current data infrastructure and connectivity

- Identify high-value use cases for initial deployment

- Plan integration with existing control systems

- Train operational staff on analytics tools

- Establish performance measurement metrics

For companies exploring industrial analytics solutions, understanding control system compatibility is crucial. Our platform offers resources for evaluating industrial automation and control system integration requirements.

Future Outlook for Industrial AI

The industrial analytics market continues evolving rapidly. Gartner predicts significant growth in AI adoption. Manufacturing sectors lead this transformation trend.

Seeq’s recognition signals broader industry shifts. Companies increasingly prioritize data-driven decision making. This trend will accelerate across process manufacturing sectors.

Frequently Asked Questions (FAQ)

What industries benefit most from Seeq’s technology?

Process manufacturing sectors including pharmaceuticals, oil and gas, chemicals, and food and beverage see significant benefits from Seeq’s industrial analytics platform.

How does Seeq integrate with existing control systems?

Seeq connects through over fifty high-performance connectors that interface directly with PLC, DCS, and other industrial control systems without requiring data migration.

What makes Seeq different from other analytics platforms?

Seeq specializes in industrial operational data, providing context-aware analytics that work directly with existing control systems rather than requiring data replication to separate platforms.