Inductive Rotary Encoders Revolutionize Precision Motion Control Applications

The Growing Demand for Advanced Encoder Technology

Industrial automation requires increasingly precise position feedback. According to MarketsandMarkets, the encoder market will reach $3.2 billion by 2027. FLUX GmbH addresses this demand with their latest whitepaper. The document explores inductive encoder benefits for critical applications.

Key Advantages of FLUX Inductive Encoders

FLUX inductive technology offers significant performance benefits:

- Exceptional immunity to magnetic interference

- Compact design with low axial profile

- High resolution and accuracy in harsh environments

- Direct integration into motor systems

- Customizable and scalable configurations

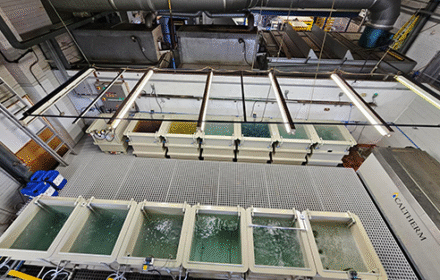

Critical Applications Across Industries

These encoders serve demanding sectors effectively. Robotics applications benefit from precision and durability. Medical equipment requires reliable position feedback. Aerospace and defense need robust performance. Industrial automation depends on accurate motion control.

Understanding Technology Limitations

The whitepaper honestly addresses application boundaries. FLUX identifies scenarios where alternative technologies might perform better. This transparency helps engineers make informed decisions. Proper technology selection ensures optimal system performance.

Expert Analysis: Industry Impact

World of PLC experts note, “Inductive encoders represent a significant advancement. They overcome traditional optical encoder limitations. Their EMI resistance makes them ideal for motor integration. However, understanding application requirements remains crucial for success.”

Implementation Considerations

Successful encoder integration requires careful planning:

- Assess environmental conditions and interference sources

- Determine required resolution and accuracy specifications

- Consider mechanical constraints and space limitations

- Evaluate customization needs for specific applications

Future Technology Trends

Encoder technology continues evolving toward higher precision. The IND-MAX series demonstrates miniaturization capabilities. Industry demands increasingly robust solutions. FLUX’s approach addresses these emerging requirements effectively.

For comprehensive motion control solutions and technical support, visit our industrial automation services page.

Frequently Asked Questions

What makes inductive encoders different from optical encoders?

Inductive encoders use electromagnetic principles instead of optical components. This makes them more resistant to contamination and magnetic interference.

Can inductive encoders operate in extreme environments?

Yes, they perform reliably in conditions with dust, moisture, and strong magnetic fields where optical encoders might fail.

What industries benefit most from inductive encoder technology?

Robotics, medical devices, aerospace, and industrial automation gain significant advantages from their robustness and precision.