Digital Optical Dissolved Oxygen Sensors Transform Industrial Process Control

Digital Optical Dissolved Oxygen Probes Enhance Operational Capabilities

Analytical sensors are vital in industrial automation, ensuring process safety, product quality, and production efficiency. In many applications, dissolved oxygen (DO) sensors are essential for optimizing aeration efficiency, monitoring microbial activity, and maintaining regulatory compliance.

As optical and digital technologies evolve, industries can now achieve more reliable process control with lower maintenance and operational costs. This article explores how digital optical DO sensors are reshaping modern measurement strategies.

Challenges with Conventional DO Sensing

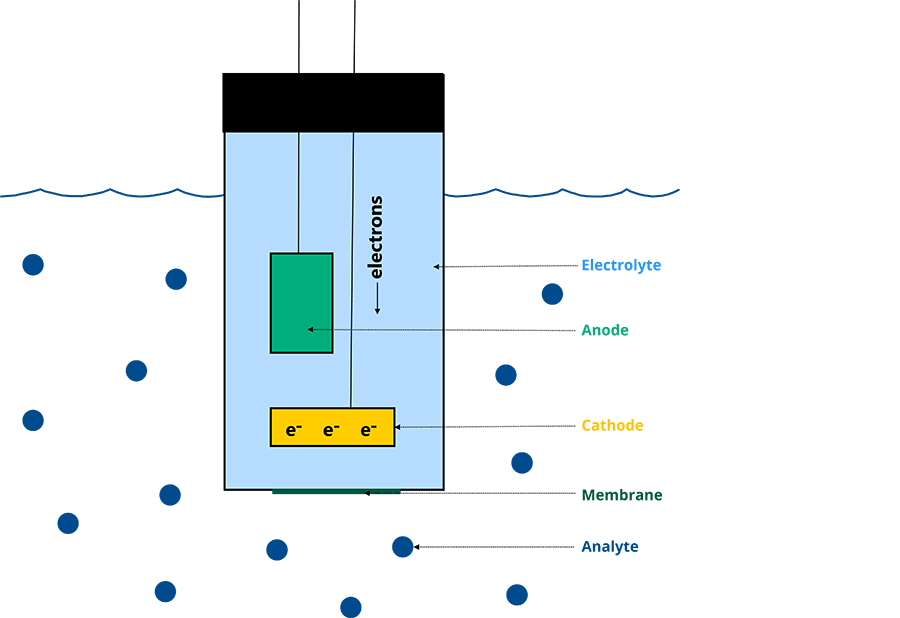

Traditional amperometric DO sensors, once the cornerstone of factory automation and process control systems, face several limitations. These sensors rely on electrochemical reactions where oxygen diffuses across a membrane to produce current. While effective, they demand significant upkeep and calibration.

Figure 1: Amperometric sensors measure dissolved oxygen through electron transfer across a membrane.

- High maintenance: Electrolyte solutions deplete and membranes foul easily, requiring frequent cleaning and replacement.

- Frequent calibration: Regular zero-point and span calibrations increase downtime and risk of manual error.

- Flow dependency: Oxygen consumption during measurement makes readings unreliable in low or no-flow conditions.

- Signal instability: Analog outputs are vulnerable to electromagnetic interference and drift over long distances.

These drawbacks not only increase total cost of ownership but also reduce operational reliability, especially in distributed control systems (DCS) and PLC-based automation environments.

Advancements in Optical DO Technology

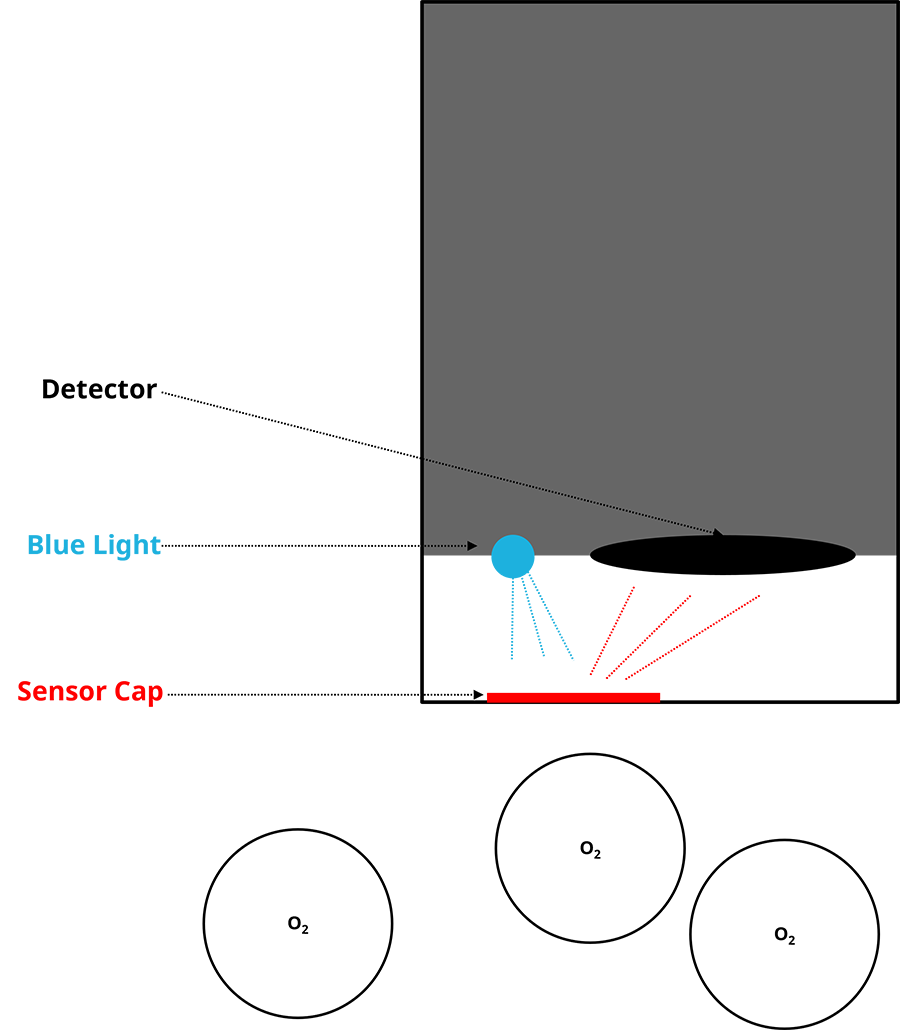

Modern luminescent optical sensors resolve many of these challenges. Using a light-emitting diode (LED) and luminescent dye, they measure oxygen concentration through fluorescence quenching, delivering accurate readings without oxygen consumption.

Figure 2: Optical sensors measure DO via fluorescence quenching, where oxygen affects light intensity and decay time.

When the LED excites dye molecules, oxygen molecules interact with them, reducing luminescence. The degree of reduction correlates directly with DO concentration. A photodiode measures the response, and the electronics calculate precise values in real time.

Figure 3: The Rosemount™ 490A Dissolved Oxygen Sensor combines optical precision with digital Modbus communication.

Optical DO sensors like the Rosemount™ 490A eliminate electrolyte refills and membrane changes. The replaceable luminescent cap lasts up to two years. Moreover, air calibration simplifies setup—no immersion required.

These sensors provide digital outputs immune to electromagnetic interference, supporting Modbus RTU and other field protocols that streamline multi-sensor configurations. This ensures reliable data transmission across extensive industrial networks.

Digital Optical Sensors in Industrial Applications

1. Wastewater Aeration Optimization

In municipal wastewater treatment, maintaining ideal DO levels in aeration basins is crucial. If oxygen is too low, microorganisms die; too high, and excess biomass forms. Conventional sensors require frequent recalibration and are prone to drift.

Figure 4: Aeration basins require precise DO monitoring to maintain microbial balance.

The Rosemount 490A digital optical sensor provides accurate readings even under low-flow conditions. Its rugged IP68-rated housing allows continuous operation in harsh environments.

By minimizing manual calibration and enabling daisy-chained connections through digital transmitters, facilities reduce wiring costs and maintenance hours—saving thousands annually in operational expenses.

2. Steam Generation and Corrosion Prevention

In power and utility systems, dissolved oxygen accelerates corrosion in boilers and condensate lines. Optical DO sensors detect minimal oxygen traces even at high temperatures and pressures, protecting equipment and extending service life.

Because they react instantly to flow or temperature variations, optical sensors outperform traditional amperometric probes in dynamic steam generation processes. They help maintain consistent quality in utility water systems and ensure compliance with ASTM and ISA standards.

Industry Insights: The Shift Toward Digital Instrumentation

According to MarketsandMarkets, the global process analytical instrumentation market will surpass $14.2 billion by 2027, driven by digital transformation and Industry 4.0 adoption.

As industrial automation evolves, digital optical DO sensors align with smart factory goals—delivering precise, stable, and low-maintenance measurement solutions.

Author’s Insight — World of PLC:

As plants transition to fully integrated automation architectures, replacing legacy analog devices with digital optical sensors is not merely a modernization step—it is a long-term investment in process reliability and operational intelligence.

Application Scenarios and Solutions

- ✅ Wastewater treatment: Improved microbial stability and energy-efficient aeration.

- ⚙️ Boiler feedwater control: Prevents corrosion and ensures heat exchanger longevity.

- 🔧 Biotechnology and food processing: Ensures product quality through precise oxygen monitoring.

For advanced automation solutions and digital DO sensors, explore World of PLC Limited for high-quality instrumentation and integration systems.

Frequently Asked Questions (FAQ)

1. How often should digital optical DO sensors be calibrated?

Most sensors require calibration only once or twice a year, depending on the application environment and regulatory requirements.

2. Can optical sensors operate in zero-flow or static liquid conditions?

Yes. Unlike amperometric sensors, optical sensors do not consume oxygen and deliver accurate readings in stagnant media.

3. Are digital optical sensors compatible with existing PLC or DCS systems?

Absolutely. They support Modbus RTU and similar protocols, ensuring seamless integration into modern and legacy control architectures.

All figures courtesy of Emerson | Authored by World of PLC Limited