Hitachi’s Major U.S. Expansion: A Strategic Move in Industrial Automation and Smart Manufacturing

Hitachi America has announced substantial new U.S. investments. These initiatives focus on advanced manufacturing and electrification. Consequently, they strengthen the company’s commitment to American infrastructure. Moreover, they create numerous high-value jobs across several states.

Strategic Vision and U.S. Market Commitment

Hitachi’s strategy aligns with its global “Inspire 2027” plan. This vision promotes a balanced society. It harmonizes environment, well-being, and economic growth. The U.S. is a critical market for this strategy. Therefore, Hitachi is deploying its digital and industrial expertise locally. Company leaders emphasize solving societal problems through technology. This approach builds on Hitachi’s founding principle of social contribution.

Digital Railcar Factory: A Lighthouse for Smart Manufacturing

Hitachi Rail opened a $100 million digital factory in Maryland. This facility serves as a global benchmark. It incorporates over $30 million in digital enhancements. The factory operates as carbon-neutral. It can produce 20 railcars monthly. Furthermore, it features a Lumada-powered AI and smart manufacturing system. This includes an immersive customer experience center. The project creates 460 direct jobs. It supports over 1,300 roles in total. The annual regional economic impact is estimated at $350 million.

Author Insight (World of PLC): This factory exemplifies the integration of IT and OT. Such digital twin environments rely heavily on robust industrial control systems. These systems ensure seamless material flow and production efficiency.

One Hitachi Collaboration in Factory Automation

The Maryland plant demonstrates Hitachi’s collaborative approach. Flexware Innovation’s LIFT intralogistics software optimizes material flow. This software was developed with Hitachi’s GlobalLogic. In addition, a private 5G network was deployed with Ericsson. This network supports real-time data exchange. It establishes the factory as a digital-first production model.

Historic Investment in U.S. Grid Infrastructure

Hitachi Energy is investing $1 billion in U.S. electrical grid infrastructure. This includes a $457 million transformer facility in Virginia. It is the largest such facility in the nation. Expansions also occur in Tennessee and Pennsylvania. Collectively, these projects will create thousands of jobs. They are essential for supporting AI data centers and renewable energy. According to Statista, the U.S. power transformer market is projected to grow significantly by 2028.

New Global HQ for Advanced Automation

JR Automation, a Hitachi group company, is building a new headquarters. The $72.8 million campus is in Zeeland, Michigan. It will house 350 employees. The facility will focus on integrated industry automation. It will leverage digital twin technology and edge computing. This hub aims to deliver next-generation intelligent manufacturing ecosystems.

Industry Leadership at the Inspire Summit

Hitachi recently hosted its Inspire Summit 2025 in Washington, D.C. The theme was “New Horizons.” It gathered over 120 delegates from 95 global brands. The event featured discussions on AI-era strategies. An Innovation Expo showcased over 45 R&D demonstrations. These highlighted Hitachi’s leadership in energy, mobility, and digital manufacturing.

Practical Applications and Solutions

Hitachi’s investments have direct industrial applications:

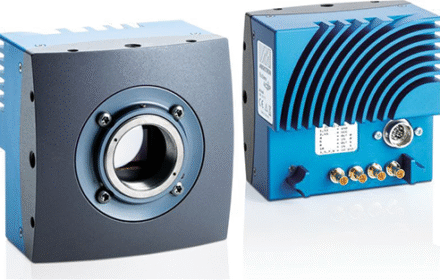

- ✅ Smart Factory Control: The Maryland plant uses advanced PLC and DCS for orchestration.

- ✅ Energy Management: New grid infrastructure supports stable power for industrial automation.

- ✅ Intralogistics Optimization: Software like LIFT enhances material handling in automated systems.

Frequently Asked Questions (FAQ)

What makes Hitachi’s Maryland factory a “lighthouse” facility?

It sets a global standard for digital, carbon-neutral manufacturing using AI and private 5G.

How do these investments impact the industrial automation sector?

They accelerate adoption of smart manufacturing, digital twins, and integrated control systems.

Why is grid infrastructure important for factory automation?

Reliable, high-quality power is essential for sensitive PLCs, DCS, and automated machinery.