Strategic Failure Management in Industrial Automation Systems

The Manufacturing Reliability Paradox

Modern manufacturers face increasing pressure for perfection. Customers expect zero defects and perfect delivery. However, supply chain disruptions create constant challenges. Skilled labor shortages compound these difficulties. Therefore, traditional cautious approaches often fail.

Understanding the Fail-Fast Methodology

Failing fast means testing ideas quickly and cheaply. It involves rapid prototyping and immediate feedback. This approach identifies problems early in development. Consequently, companies avoid costly late-stage failures.

Real-World Semiconductor Manufacturing Case

Bullen Ultrasonics faced a critical semiconductor contract threat. Their customer demanded higher output with changing specifications. The company implemented structured experimentation. They achieved 30% productivity improvement within weeks.

Industrial Automation Implementation Framework

Successful fail-fast systems require specific components:

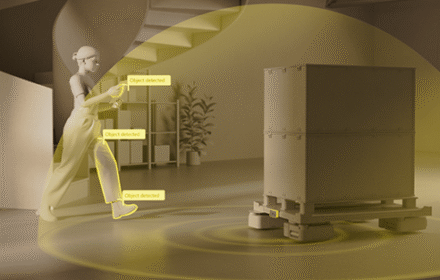

Real-time performance monitoring dashboards

Automated quality control checkpoints

Cross-functional team collaboration

Rapid prototyping capabilities

Continuous improvement processes

Workforce Development Strategies

Manufacturers must invest in technical training programs. According to NAM, 75% of manufacturers report workforce shortages. Structured skill development prevents operational failures. Moreover, it enables faster problem-solving.

Technology Integration for Rapid Learning

Modern PLC and DCS systems enable quick testing. Industrial automation platforms support virtual commissioning. Therefore, engineers can simulate changes before implementation. This reduces physical prototyping costs significantly.

Quality Control System Enhancements

Early defect detection saves substantial resources. Statistical process control identifies variation patterns. Automated inspection systems catch deviations immediately. As a result, manufacturers prevent batch failures.

Expert Analysis from World of PLC

Industrial automation systems transform failure management. Properly implemented control systems enable safe experimentation. For advanced manufacturing solutions, visit World of PLC. Our expertise ensures reliable system integration.

Implementation Roadmap for Manufacturers

Start with small-scale pilot projects. Establish clear success metrics. Train teams on rapid iteration techniques. Gradually expand to larger systems. Monitor results and adjust accordingly.

Frequently Asked Questions

How does failing fast differ from being careless?

Structured failing fast uses controlled experiments with defined boundaries, while carelessness lacks planning and measurement.

What industries benefit most from this approach?

High-tech manufacturing, semiconductor production, and automotive sectors show the greatest benefits from rapid iteration strategies.

How do you measure fail-fast initiative success?

Track time-to-resolution for problems, innovation implementation rates, and customer satisfaction improvements.

This analysis demonstrates how strategic failure management drives manufacturing excellence. Always consult with qualified automation engineers for specific implementations.