Optimizing Parallel Pump Systems for Maximum Energy Efficiency

Revolutionizing Industrial Pump Control Strategies

Parallel pump systems offer significant energy savings opportunities. Variable speed drives optimize flow control efficiently. This approach reduces power consumption substantially. It also extends equipment lifespan effectively.

Solar Thermal Plant Application Case Study

Plataforma Solar de Almeria demonstrates advanced pump optimization. Their parabolic trough collector system requires precise control. Flow rates vary significantly throughout daylight hours. System head requirements change even more dramatically.

Parallel Pump System Advantages

Multiple smaller pumps provide superior operational flexibility. They enhance system reliability and reduce downtime. Maintenance becomes easier and more cost-effective. Key benefits include:

- Increased system reliability and uptime

- Reduced energy consumption significantly

- Lower maintenance costs and easier repairs

- Better utilization of standard pump models

Variable Speed Drive Technology Benefits

Variable speed drives outperform traditional throttling methods. They adjust pump speed to match exact requirements. This eliminates energy waste from flow restriction. Energy savings typically reach 30-50 percent.

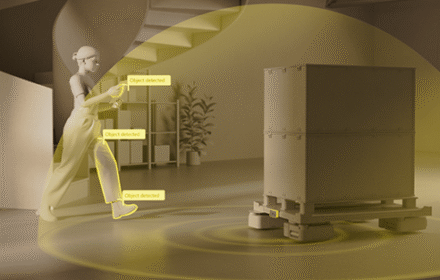

Advanced Control System Implementation

Model-based control optimizes pump operation continuously. The system analyzes real-time performance data. It calculates the most efficient pump configuration. This includes determining:

- Optimal number of active pumps

- Ideal pump operating speeds

- Most efficient valve positions

- Best efficiency point operation

Energy Savings Documentation

Research demonstrates substantial power reduction benefits. Optimized parallel pump systems save significant energy. The Plataforma Solar study shows consistent results. Documented achievements include:

- 3.4% daily energy savings average

- 90% power reduction during low demand

- Extended pump maintenance intervals

- Improved system reliability metrics

Industrial Application Versatility

These optimization principles apply across multiple industries. Water distribution systems benefit significantly. HVAC and industrial processes show similar improvements. Any parallel pump application can achieve savings.

Market Context and Energy Trends

Industrial energy efficiency gains increasing importance. According to Statista, global energy management systems will reach $63 billion by 2026. Pump optimization represents a major opportunity. Companies seek solutions that reduce operational costs.

Implementation Best Practices

Successful optimization requires systematic approach. Companies should follow proven methodology. This ensures maximum benefits and reliable operation. Key steps include:

- Comprehensive system analysis and modeling

- Proper variable frequency drive selection

- Advanced control system integration

- Continuous monitoring and optimization

Expert Recommendations and Solutions

Proper pump system optimization delivers substantial returns. At World of PLC, we recommend starting with energy audits. Identify the highest savings opportunities first. Explore our industrial automation solutions for pump optimization projects.

Frequently Asked Questions

What are the main benefits of parallel pump systems?

Parallel systems provide better reliability and energy efficiency. They allow maintenance without shutdown and optimize energy use.

How much energy can variable speed drives save?

Typical savings range from 30-50% compared to throttling. The exact amount depends on system design and operation.

Which industries benefit most from pump optimization?

Water treatment, HVAC, manufacturing, and energy production show strongest results. Any industry using pumps can achieve savings.

Strategic Implementation Approach

Parallel pump optimization delivers proven energy savings. The technology continues evolving with smarter controls. Early adopters gain competitive advantages. Companies should evaluate their pump systems now.