Coriolis Flowmeters Continue to Dominate the Worldwide Flowmeter Market

Coriolis Flowmeters Lead Industrial Measurement Market with Advanced Technology

Strong Market Growth Projections

The global Coriolis flowmeter market demonstrates robust expansion. Flow Research’s latest study reveals a $1.9 billion market in 2024. Projections indicate growth to $2.4 billion by 2029. This represents a 6.2% compound annual growth rate.

Historical Innovation and Development

Micro Motion introduced the first Coriolis flowmeter in 1977. The technology has evolved significantly over four decades. Today’s models offer unprecedented accuracy and reliability. They outperform many competing flow measurement technologies.

Technical Advancements and Accuracy

Modern Coriolis meters provide exceptional measurement precision. Advanced diagnostic software monitors performance continuously. This technology predicts recalibration needs proactively. Manufacturers constantly push performance boundaries.

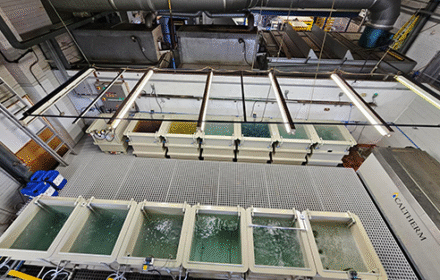

Design Innovations: Straight Tube Advantages

Straight tube designs solve traditional clogging issues. Both single and dual tube configurations are available. These meters require minimal straight pipe runs. Their compact size fits space-constrained installations.

Expanded Size Range Applications

Coriolis meters now cover extreme size requirements. Large 6-16 inch models handle custody transfer applications. They measure petroleum liquids and natural gas accurately. Meanwhile, tiny 1/16 inch meters serve specialized applications.

Specialized Small-Scale Applications

Miniature Coriolis meters enable precise chemical injection. They handle catalyst and treatment chemical dosing. Pharmaceutical and food industries use them for batching. These meters manage expensive additives and fragrances effectively.

Competitive Market Positioning

Coriolis meters compete strongly in 2-4 inch pipe sizes. They challenge ultrasonic and turbine meter dominance. Their APA-11 approval enables natural gas fiscal metering. High accuracy makes them ideal for critical applications.

Energy Sector Applications

Natural gas measurement represents a key application area. Coriolis meters measure boiler and furnace feed accurately. They serve CNG and LNG distribution stations effectively. Density measurement provides additional process value.

Lifecycle Cost Advantages

Coriolis meters offer superior long-term value despite higher initial costs. They contain no moving parts except vibrating tubes. This design eliminates wear-related maintenance. Reduced staffing makes low maintenance crucial.

Material Science Innovations

New construction materials enhance meter durability. Titanium provides strength while reducing weight. Super duplex materials resist pitting corrosion. These advances handle corrosive fluids effectively.

Expert Industry Perspective

Flow Research President Dr. Jesse Yoder emphasizes Coriolis importance. Suppliers continuously improve accuracy and materials. They develop application-specific models consistently. Coriolis technology leads energy transition measurements.

Future Market Trajectory

Coriolis meters will measure hydrogen and renewable natural gas. They support global energy transition initiatives. World of PLC analysis confirms their ongoing market dominance. Technological innovation drives continued adoption.

Key Industrial Applications

Coriolis meters serve multiple critical industries:

- Oil and Gas Custody Transfer

- Pharmaceutical Ingredient Batching

- Chemical Process Measurement

- Food and Beverage Production

- Energy Distribution Systems

Technical Superiority Factors

Several features explain Coriolis market leadership:

- Superior accuracy across flow ranges

- Multivariable measurement capability

- Minimal maintenance requirements

- Corrosion-resistant materials

- Advanced diagnostic capabilities

For comprehensive industrial automation solutions and technical resources, visit World of PLC to explore how advanced flow measurement can optimize your processes.

Frequently Asked Questions

What makes Coriolis flowmeters more accurate than other types?

Coriolis meters measure mass directly rather than inferring it from other parameters, providing superior accuracy unaffected by fluid properties changes.

Are Coriolis flowmeters suitable for abrasive fluids?

Modern materials like super duplex stainless steel and titanium provide excellent abrasion resistance, making them suitable for many challenging fluid applications.

How do Coriolis meters support Industry 4.0 initiatives?

Advanced diagnostics and digital communication protocols enable predictive maintenance and seamless integration with industrial IoT systems and control networks.

Process Optimization Case Study: A chemical processing plant struggled with inaccurate batching measurements using traditional flowmeters. After installing Coriolis meters with advanced diagnostics, they achieved 99.8% measurement accuracy, reduced product giveaway by 15%, and eliminated quarterly calibration downtime through predictive maintenance capabilities.