COMAU Demonstrates AI’s Impact on Industrial Automation at ETFA 2025

COMAU Highlights AI’s Potential to Promote the Development of the Industrial System at ETFA 2025

Event Overview and Strategic Focus on Factory Automation

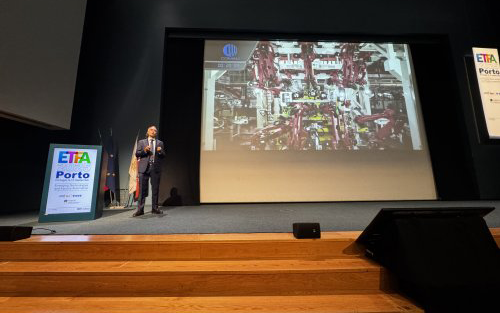

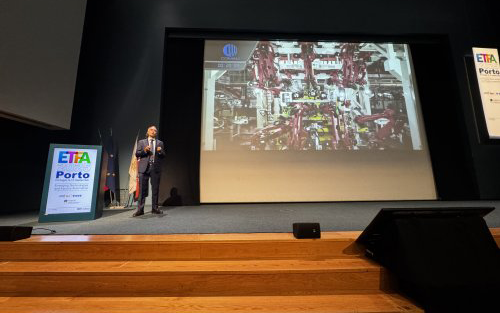

COMAU presented its AI strategy at ETFA 2025 in Porto, Portugal. The event ran from September 9 to 12.

Moreover, industry leaders discussed enabling technologies for modern factory automation.

AI for Advanced Robotics and Control Systems

Giovanni Di Stefano described using industrial heritage to train advanced neural networks.

As a result, COMAU applies machine learning to improve robotic motion and quality.

According to MarketsandMarkets, industrial AI adoption continues to accelerate globally.

Data-Rich PLM Enables Real-World AI Models

COMAU leverages decades of PLM data to train production-grade AI models.

Therefore, AI models reflect real use cases rather than synthetic scenarios.

This approach improves precision in PLC-and-robotics-related control tasks.

Practical AI Tools and Use Cases

COMAU showcased several AI-driven products and solutions at ETFA.

For example, joint-stiffness analysis improves trajectory quality and reduces wear.

In addition, AI-assisted gripper design shortens engineering cycles and lowers cost.

- MI.RA/OnePicker — AI vision for autonomous object picking in logistics.

- MI.RA/Thermography — In-line AI inspection for welding quality in batteries.

- Joint Stiffness Tools — AI-derived measures to enhance motion fidelity.

Industry Impact and Metrics

AI integration enables predictive maintenance and higher uptime in production.

Moreover, Statista reports most manufacturers now invest in AI for efficiency gains.

As a result, companies see measurable improvements in yield and consistency.

Author Commentary — World of PLC

From World of PLC’s perspective, COMAU’s approach shows how AI complements PLC and DCS platforms.

In practice, hybrid architectures combine rule-based control with learned models.

We recommend piloting AI components on non-critical lines first, then scaling gradually.

Application Scenarios and Solution Patterns

- Battery assembly: AI thermography for weld quality verification.

- Automotive: AI-driven grippers reduce changeover time and scrap.

- Logistics: Vision-guided picking increases throughput and accuracy.

Implementation Steps for Integrating AI with Automation

- Collect historical PLM and runtime data from PLCs and robots.

- Validate dataset quality and label real production examples.

- Train models on representative cases, then test in a sandbox.

- Deploy models with monitoring and rollback mechanisms.

About COMAU

COMAU is a global leader in automation, robotics, and digital manufacturing.

Together with Automha, the company serves vehicle manufacturing and many other sectors.

COMAU’s portfolio supports e-mobility, logistics, pharma, and renewable energy.

FAQs

1. How does COMAU apply AI to factory automation?

COMAU trains AI with PLM and production data to optimize robotics and vision systems.

2. Can AI be integrated with existing PLC or DCS systems?

Yes. COMAU integrates AI as complementary modules that augment PLC and DCS control logic.

3. What are practical first steps for adopters?

Start with a pilot on a non-critical line, gather real data, and validate results objectively.

Explore Relevant Products

To view automation components and compatible products, visit World of PLC Limited.