Planon Recognized as an Industry Leader in CMMS by Independent Research Firm

Industrial Maintenance Management: CMMS Solutions for Smart Facilities

Planon achieves leadership position in computerized maintenance management systems. This recognition highlights advanced industrial automation integration capabilities.

Industry Recognition and Leadership Position

Planon earns Leader status in Verdantix Green Quadrant for CMMS. The independent research firm evaluates commercial building maintenance solutions. This recognition occurs in their 2025 comprehensive market assessment.

Technical Capabilities and System Strengths

Verdantix analysts identify several Planon competitive advantages:

- Upgrade-safe configurability for system modifications

- IoT-led automation for connected device management

- No-code workflows for business process customization

- Predictive maintenance through partner integrations

- Digital twin functionality for virtual asset management

Market Context and Industry Challenges

Commercial building owners face multiple operational pressures. Labor costs continue rising significantly across markets. Aging infrastructure requires more maintenance attention. Regulatory compliance demands increase operational complexity.

Expert Analysis and Market Perspective

Joy Trinquet from Verdantix explains current market dynamics. Organizations replace legacy systems with modern CMMS solutions. These systems optimize resources and streamline maintenance operations. They maximize return on investment through efficiency improvements.

Company Leadership Vision and Strategy

Peter Ankerstjerne emphasizes Planon’s commitment to innovation. The recognition validates their Asset & Maintenance Management solution. It demonstrates strength in current functionality and future roadmap. The platform supports efficiency, compliance and sustainability goals.

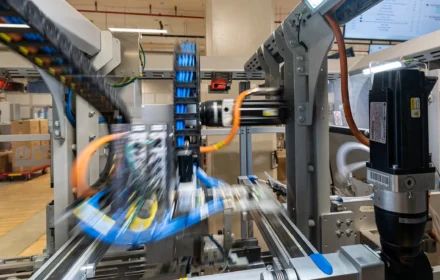

Technical Integration with Industrial Automation

Planon’s solution integrates with multiple industrial systems:

- PLC and DCS systems for equipment monitoring

- Building automation systems for environmental control

- IoT sensors for real-time data collection

- Enterprise systems for comprehensive reporting

- Mobile platforms for field service management

Research Methodology and Evaluation Criteria

Verdantix conducts independent research every two years. They assess software capabilities and market momentum. Strategic success metrics include several key factors:

- Vision and strategy development and execution

- Installed customer base size and satisfaction

- Organizational and financial resource allocation

- IT systems integration capabilities

- Business intelligence and reporting features

Industrial Maintenance Market Trends

World of PLC identifies several important developments:

- Increased CMMS and industrial automation integration

- Predictive maintenance adoption across industries

- Digital twin implementation for asset management

- Mobile workforce enablement through technology

- Cloud-based maintenance management solutions

Practical Application: Manufacturing Facility

A major manufacturer implemented Planon’s CMMS solution recently. They integrated PLC systems with maintenance management. The project reduced equipment downtime by 35% annually. Maintenance costs decreased through predictive scheduling.

Implementation Considerations for Industrial Facilities

World of PLC recommends these implementation steps:

- Assess current maintenance processes and pain points

- Evaluate integration requirements with existing systems

- Plan data migration and system configuration carefully

- Train maintenance staff on new workflows and features

- Establish performance metrics and monitoring procedures

Future Maintenance Management Directions

Industrial maintenance continues evolving rapidly:

- Artificial intelligence for predictive analytics

- Augmented reality for maintenance guidance

- Blockchain for maintenance record security

- 5G connectivity for real-time data transmission

- Sustainability integration for green operations

Next Steps for Facility Management Professionals

Industrial leaders should evaluate maintenance management needs. Consider CMMS solutions for operational improvement. Plan system integration with existing automation. Implement pilot projects to validate benefits.

For industrial automation solutions that complement CMMS implementations, explore World of PLC’s control systems portfolio. Our expertise supports comprehensive maintenance optimization.

Frequently Asked Questions

What distinguishes leading CMMS solutions from basic systems?

Leading solutions offer predictive maintenance and IoT integration. They provide no-code workflow customization and digital twin capabilities. Advanced analytics and reporting differentiate them significantly.

How does CMMS integration benefit industrial automation?

Integration enables predictive maintenance for PLC and DCS systems. It reduces equipment downtime and maintenance costs. Operational efficiency improves through coordinated management.

What evaluation criteria matter most for CMMS selection?

System capabilities and integration features prove most important. Vendor stability and implementation support also matter significantly. Total cost of ownership and return on investment determine value.