AI-Powered Vision Inspection Revolutionizes Industrial Automation Quality Control

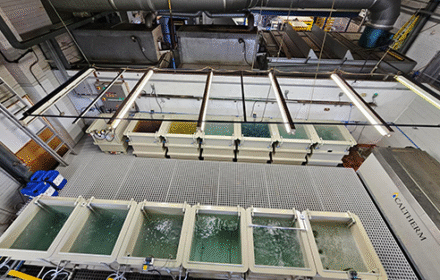

EZ Automation unveils innovative inline configuration for PIQuE inspection system at ISA Automation Summit. This advanced solution transforms quality control in modern manufacturing environments.

Next-Generation Inline Inspection Technology

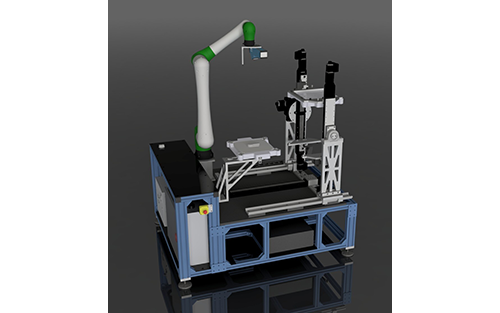

EZ Automation introduces a groundbreaking inline version of its PIQuE system. The new configuration eliminates robotic manipulation components from the original design. Instead, it integrates directly into production lines for seamless operation.

The system maintains advanced 3D laser triangulation capabilities. AI-driven inspection algorithms ensure precise defect detection. This approach delivers faster, more accurate quality control for factory automation.

Advanced AI and Machine Learning Capabilities

PIQuE leverages EZ Eye vision processing framework for superior performance. Pre-trained AI models enable rapid deployment without extensive setup. The system continuously improves through adaptive learning functionality.

Key AI features include:

- ✅ Automatic adjustment to surface variations

- ✅ Continuous accuracy improvement over time

- ✅ Reduced false rejection rates

- ✅ Historical data analysis for optimization

Practical Applications Across Manufacturing Sectors

The inspection system serves multiple high-precision industries effectively. Electronics manufacturing benefits from PCB damage detection and component alignment verification. Semiconductor production achieves superior quality control standards.

Medical device and aerospace manufacturers utilize the technology for critical inspections. Automotive and consumer goods industries maintain stringent quality requirements. The system detects minute surface variations with exceptional accuracy.

Plug-and-Play Implementation Advantages

Traditional vision systems often require complex commissioning processes. PIQuE operates as a true plug-and-play solution. Cloud-based analytics and remote monitoring enhance operational efficiency.

EZ Automation provides comprehensive one-year remote support. This ensures smooth integration into existing industrial automation systems. Manufacturers achieve rapid ROI through reduced downtime.

World of PLC Perspective: AI in Modern Industrial Automation

At World of PLC, we recognize AI’s transformative impact on quality control systems. The manufacturing AI market will reach $16.7 billion by 2026 according to MarketsandMarkets. This represents significant growth opportunities.

Integration considerations for automation professionals:

- ⚙️ Compatibility with existing PLC and DCS systems

- ⚙️ Network infrastructure requirements

- ⚙️ Data security protocols for cloud connectivity

- ⚙️ Training requirements for operations staff

AI-powered inspection systems require robust control systems infrastructure. Proper integration ensures optimal performance in factory automation environments.

Discover industrial automation solutions at World of PLC’s control systems platform for AI-ready manufacturing infrastructure.

Live Demonstration at ISA Automation Summit

Booth 310 at the Lake Buena Vista event features hands-on PIQuE experience. Attendees can observe real-time surface inspection capabilities. The demonstration highlights the system’s flexibility for various production environments.

Ahmed Tawfik, EZ Automation CEO, emphasizes their commitment to practical solutions. “PIQuE addresses real-world manufacturing challenges effectively,” Tawfik states. “The system’s flexibility meets dynamic production needs.”

Global Presence and Industry Leadership

EZ Automation maintains operations across eight countries worldwide. Their international footprint includes the United States, Australia, Japan, and European markets. The company specializes in turnkey automation solutions for diverse industries.

Frequently Asked Questions

How does AI-powered inspection differ from traditional vision systems?

AI systems learn and adapt to variations automatically, while traditional systems require manual programming adjustments. This reduces setup time and improves accuracy over continuous operation.

What industries benefit most from inline inspection systems?

Electronics, semiconductor, medical device, and aerospace manufacturing achieve significant quality improvements. These sectors require high-precision defect detection for product reliability.

How difficult is integration with existing automation infrastructure?

Modern systems like PIQuE designed for seamless integration. They connect with standard PLC and DCS systems through common industrial communication protocols.

About EZ Automation Systems

EZ Automation Systems delivers intelligent automation solutions globally. The company specializes in AI-driven inspection and robotic vision technologies. Their custom turnkey solutions enhance precision and efficiency across multiple manufacturing sectors.