Advanced Surface Treatment Expansion Meets Critical Defense and Aerospace Standards

Strategic Infrastructure Investment

Captec announces major surface treatment facility upgrades. The company now meets stringent BR 3939 Warpaint standards. This positions them among elite UK providers. Moreover, it enhances their defense and aerospace capabilities.

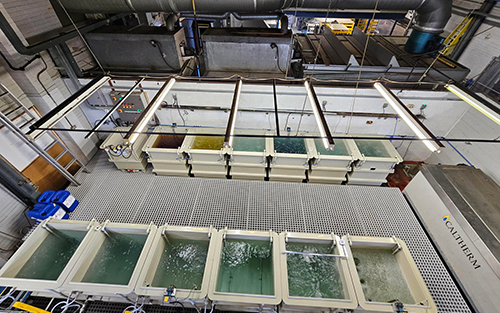

Technical Capacity Expansion

The facility upgrade doubles processing capacity significantly. Captec expanded from six to twelve treatment tanks. This configuration supports advanced chemical processing. Therefore, it enables next-generation surface treatments.

Partnership with Industry Leader

Captec collaborated with SurTec for this upgrade. SurTec represents a global surface treatment specialist. Their technologies ensure reliability in extreme environments. Additionally, they provide best-in-class chemical specifications.

Enhanced Performance Characteristics

The new capabilities deliver exceptional corrosion resistance. They provide ultra-low surface resistance properties. Furthermore, they create optimal bases for coatings. These features meet highest BR 3939 compliance levels.

Defense and Aerospace Applications

Mission-critical systems require advanced surface treatments. The global defense coatings market exceeds $2.1 billion annually. Captec now qualifies for elite defense programs. Consequently, they support high-assurance platforms effectively.

Industry Certification Importance

BR 3939 standards ensure material performance longevity. They address extreme environmental resistance requirements. Manufacturers must meet these standards for defense contracts. According to MarketsandMarkets, the protective coatings market grows at 6.2% CAGR.

Leadership Perspectives

“This upgrade marks a critical milestone for Captec,” stated Phill Gower. “Our defense partners benefit from highest standard treatments. The expansion significantly enhances our engineering capabilities.”

Technology Partner Recognition

René Lecomte of SurTec acknowledged Captec’s commitment. “Captec mirrors SurTec’s quality philosophy perfectly. We proudly support their strategic upgrade. They now rank among UK’s most capable providers.”

Industrial Automation Integration

Surface treatment requires precise process control. Automated systems maintain chemical bath consistency. PLC-controlled sequences ensure repeatable quality. Furthermore, DCS manages overall facility operations.

Industry Event Participation

Captec will showcase at DSEI defense exhibition. The event features latest security technologies. Visitors can see surface treatment demonstrations. Additionally, they can discuss integrated system solutions.

Technical Implementation Features

✅ Double tank capacity for increased throughput

⚙️ Advanced chemical processing capabilities

🔧 Extreme environment resistance treatments

🔬 Precision quality control systems

World of PLC Industry Analysis

Surface treatment automation demands sophisticated controls. Process consistency ensures compliance with military standards. Moreover, automated systems reduce human error. Manufacturers should evaluate their automation infrastructure.

For industrial automation systems that ensure process consistency in manufacturing, explore World of PLC’s control solutions designed for precision manufacturing applications.

Quality Assurance Applications

Defense contractors require documented process control. Automated systems provide necessary audit trails. They also ensure consistent treatment results. Therefore, they support compliance certification efforts.

Frequently Asked Questions

What industries require BR 3939 compliance?

Defense, aerospace, and maritime sectors primarily need these standards. They ensure performance in extreme environments.

How does automation improve surface treatment?

Automation ensures process consistency and repeatability. It also provides comprehensive quality documentation.

What benefits does doubled capacity provide?

Increased throughput reduces lead times significantly. It also supports larger defense program requirements.