How 3D Printing Transforms Industrial Automation and Manufacturing

The Additive Manufacturing Revolution

Mouser Electronics launched its latest Empowering Innovation Together series. The program explores 3D printing’s impact on industrial automation. Additive manufacturing now integrates AI and advanced materials. Consequently, it transforms traditional design and production workflows.

Advanced Manufacturing Capabilities

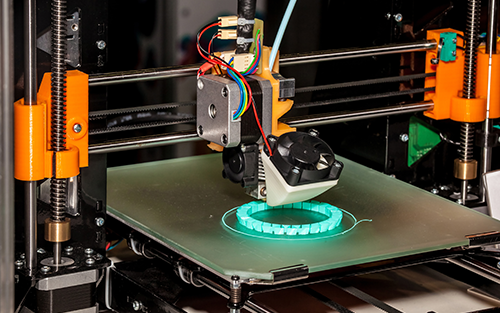

3D printing creates complex geometries impossible with traditional methods. It produces intricate internal structures and lightweight components. Manufacturers achieve unprecedented design freedom. This flexibility accelerates innovation across multiple industries.

Real-World Industrial Applications

Additive manufacturing now produces FAA-approved titanium components. It also creates biomedical implants from advanced biomaterials. These applications demonstrate the technology’s maturity. Industries benefit from customized, high-strength parts.

AI Integration and Material Science

Artificial intelligence optimizes 3D printing processes. AI algorithms enhance design precision and material usage. New materials expand application possibilities. Together, they drive manufacturing efficiency and capability.

Industry Expert Perspectives

Mouser’s podcast features 3D printing industry leaders. Mark Beatty of 3D Agility discusses manufacturing transformation. Stefanie Brickwede explores additive manufacturing networks. They address both advantages and adoption challenges.

Market Growth and Statistics

The global 3D printing market shows remarkable expansion. According to Statista, market volume will reach $44.5 billion by 2026. Industrial automation drives significant growth. Manufacturers increasingly adopt additive technologies.

Supply Chain Advantages

3D printing solves critical supply chain challenges. It enables localized spare parts production. Companies reduce inventory costs significantly. On-demand manufacturing becomes practical and efficient.

Key Benefits for Industrial Automation

• Rapid prototyping accelerates product development

• Customized components enhance machine performance

• Reduced material waste lowers production costs

• Complex geometries improve system efficiency

• Localized production shortens lead times

Author’s Insight from World of PLC

3D printing revolutionizes industrial control systems manufacturing. It enables custom PLC enclosures and specialized components. Maintenance teams print obsolete parts on-demand. This technology complements traditional factory automation systems. Engineers should explore additive manufacturing for control system enhancements.

Implementation Strategy for Manufacturers

Start with prototyping and tooling applications. Then progress to end-use part production. Invest in employee training and process development. Finally, integrate additive manufacturing into main production lines.

Future Trends and Developments

Multi-material printing will expand capabilities. Larger format printers will enable bigger components. Speed improvements will increase production volumes. These advances will further transform manufacturing.

Practical Application Scenario

Situation: Manufacturing plant needs custom sensor mounts

Traditional Approach: Machine from solid block (5 days lead time)

3D Printing Solution: Design and print overnight

Result: 80% faster implementation, 60% cost reduction

Frequently Asked Questions

Can 3D printed parts withstand industrial environments?

Yes. Advanced materials like carbon-fiber composites and industrial polymers meet rigorous requirements. They withstand vibration, temperature variations, and chemical exposure.

How does 3D printing affect control systems design?

It enables custom enclosures, cable management systems, and mounting solutions. Engineers optimize layouts without traditional manufacturing constraints.

What industries benefit most from industrial 3D printing?

Aerospace, automotive, medical devices, and industrial automation lead adoption. These sectors value customization, lightweighting, and complex geometries.

About Mouser’s Educational Initiative

The Empowering Innovation Together program began in 2015. It provides valuable technical education resources. The series includes podcasts, videos, and technical articles. Engineering professionals worldwide benefit from this content.